Injection Unit

Power Unit

Clamping Unit

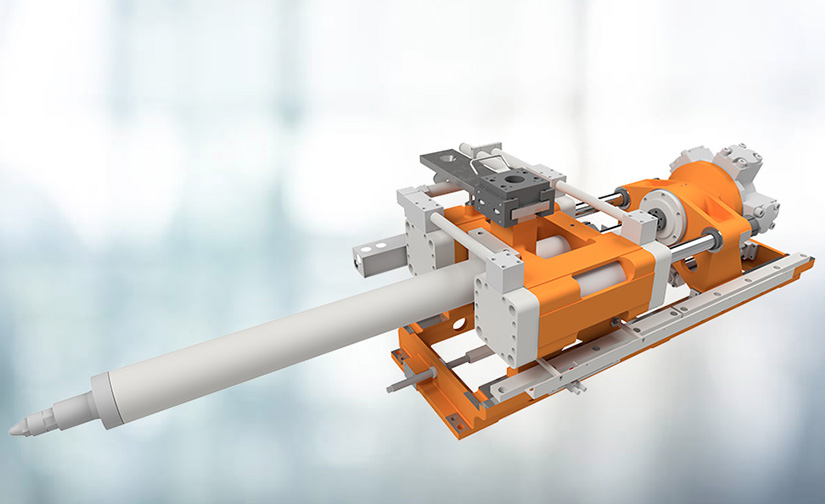

Single Injection

ー Professional design team makes the injection barrel according to plastic material

The production demand for plastic finished products is a single plastic material.

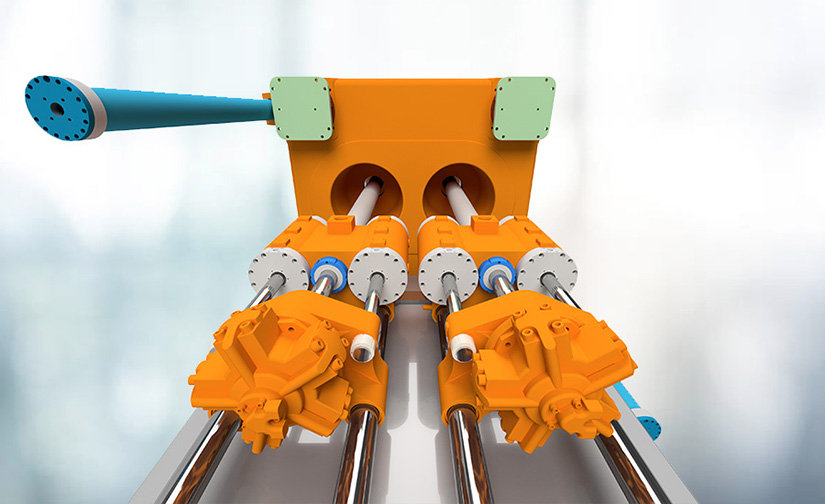

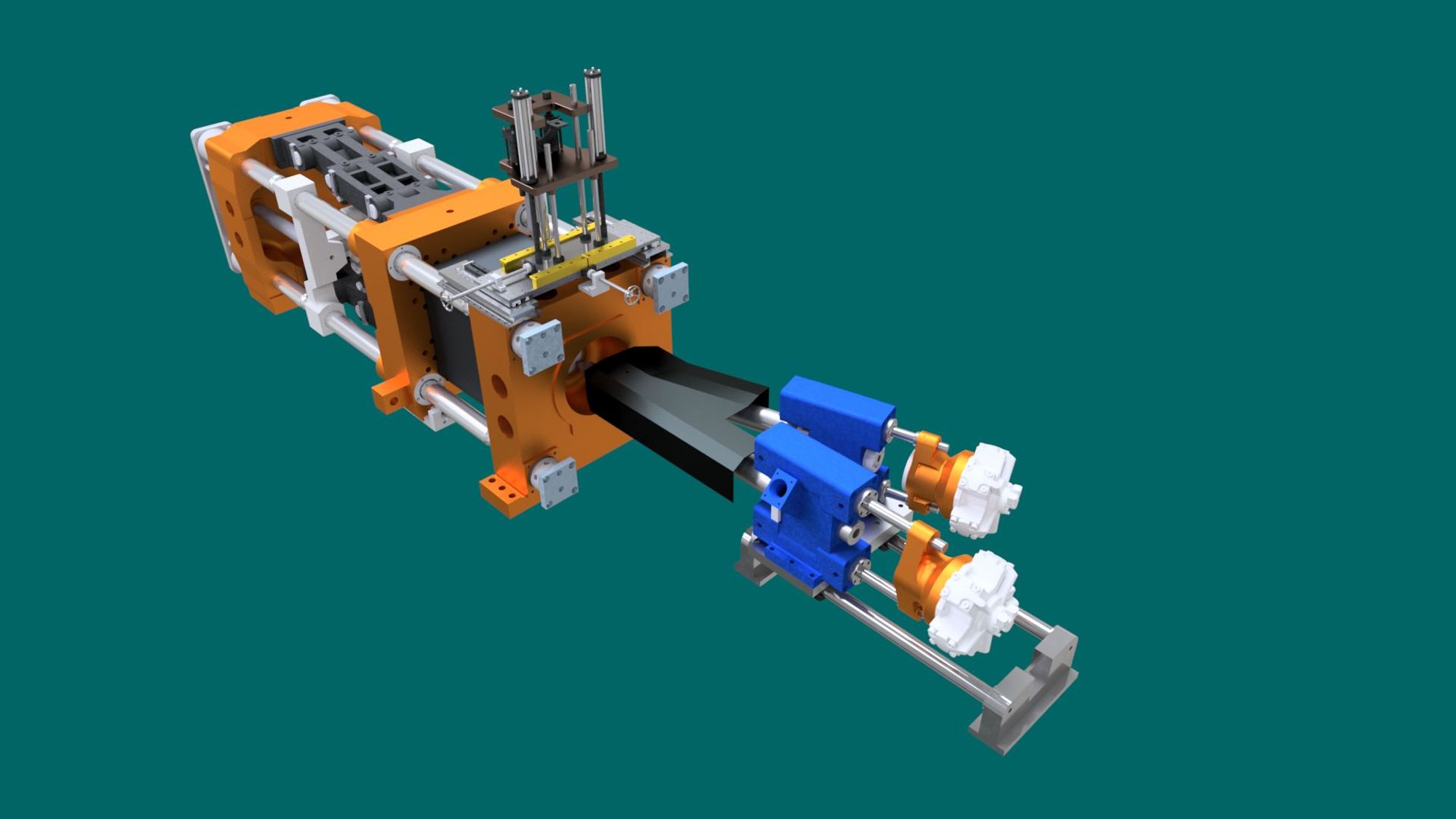

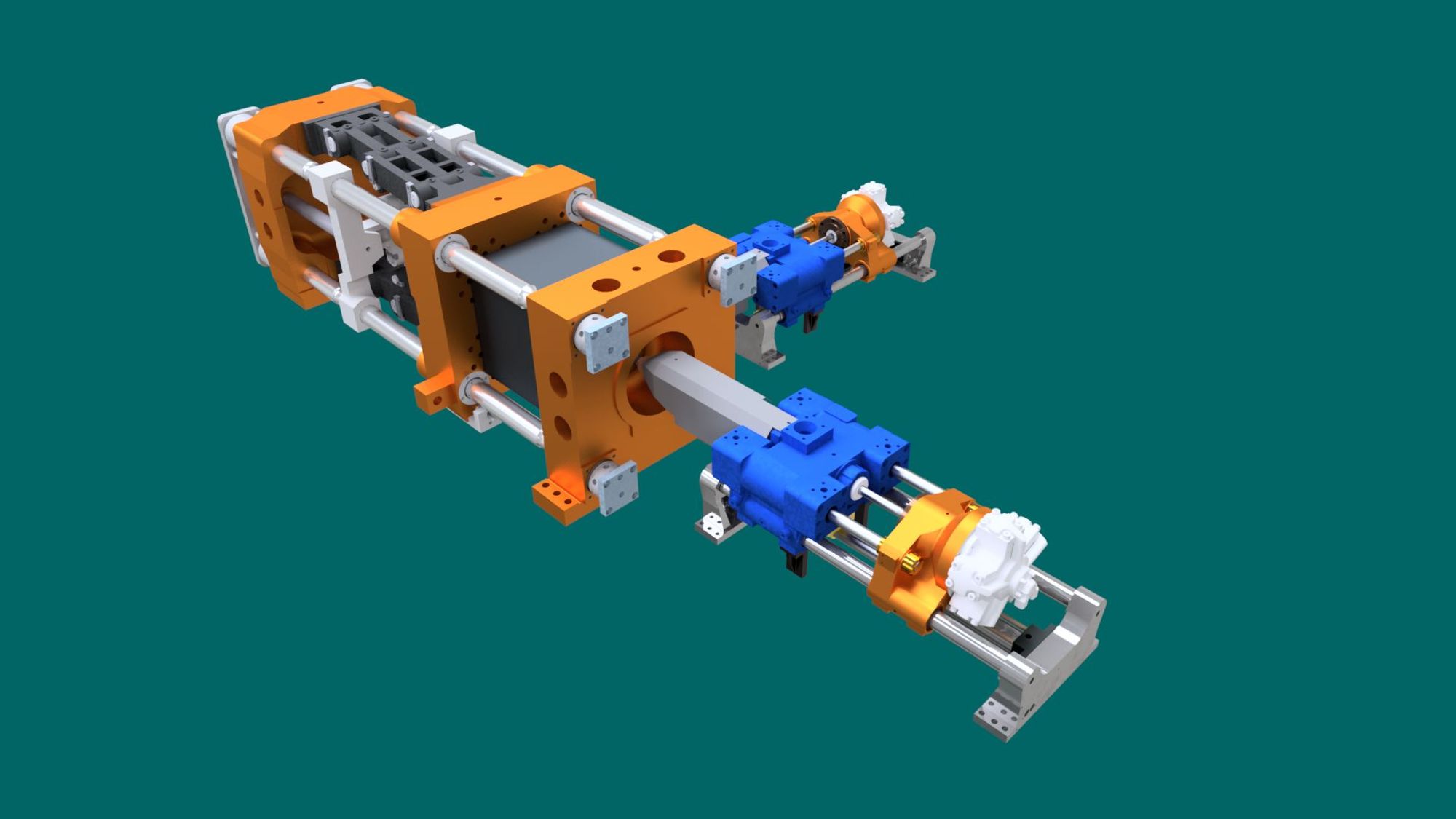

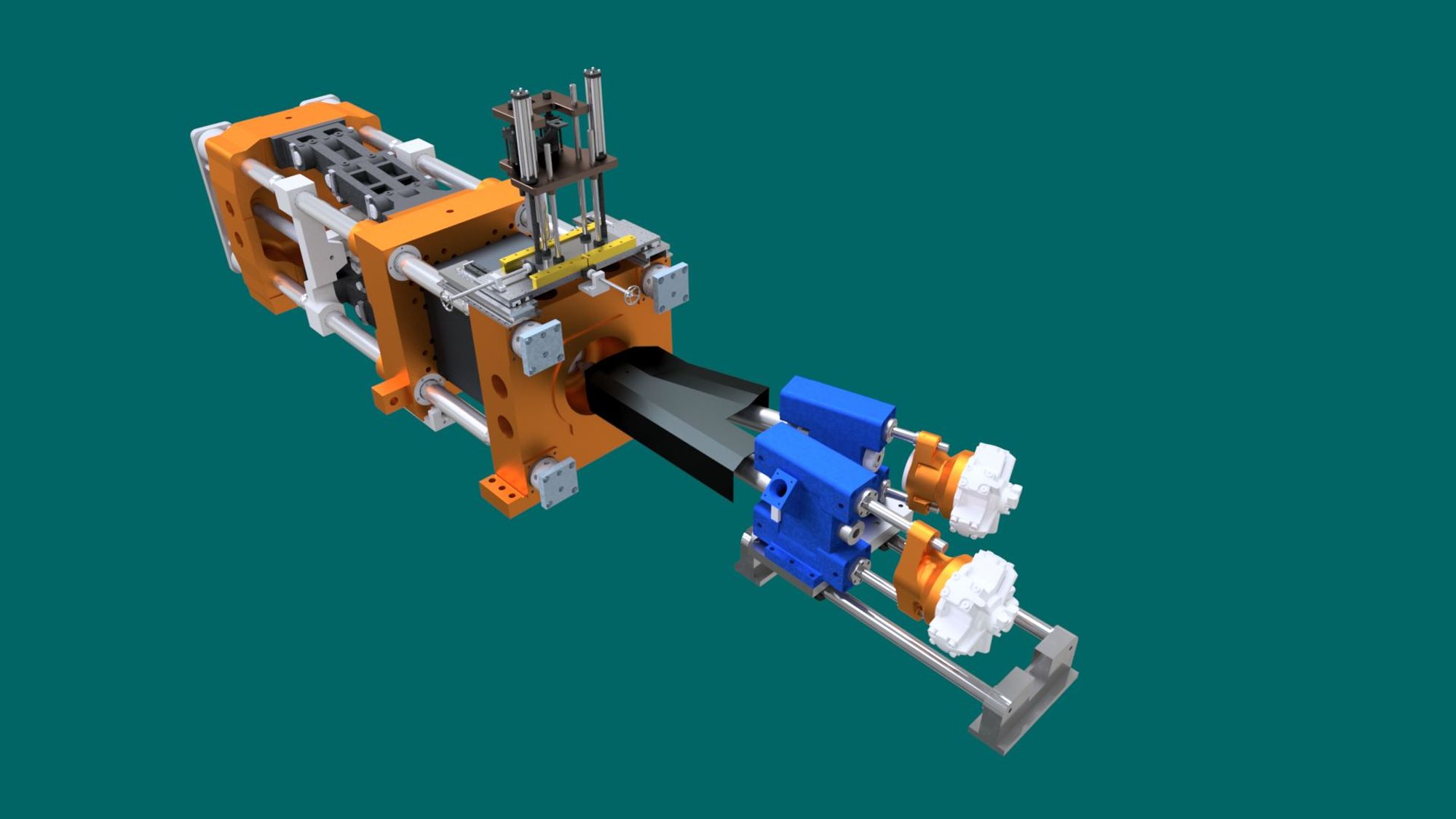

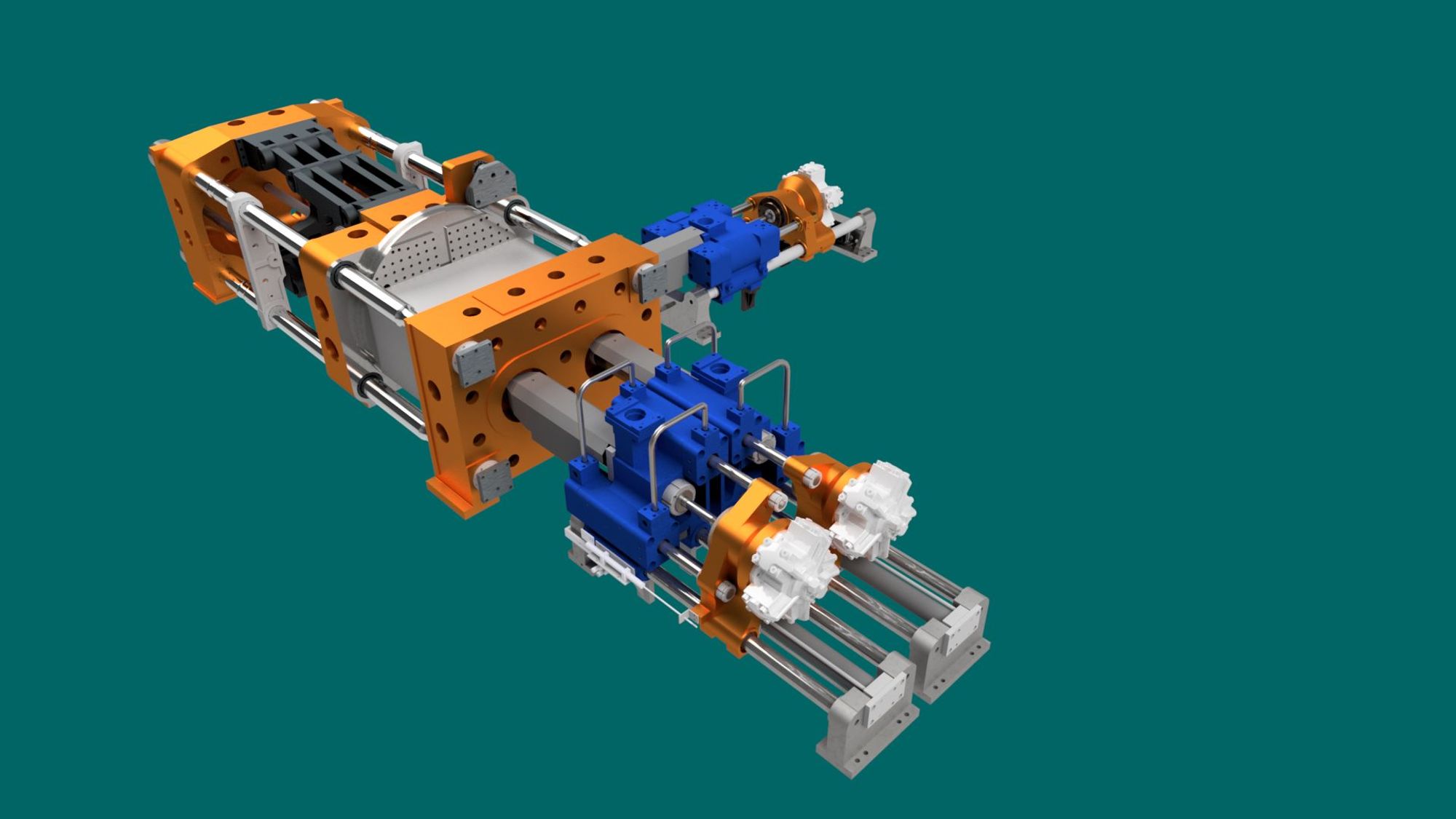

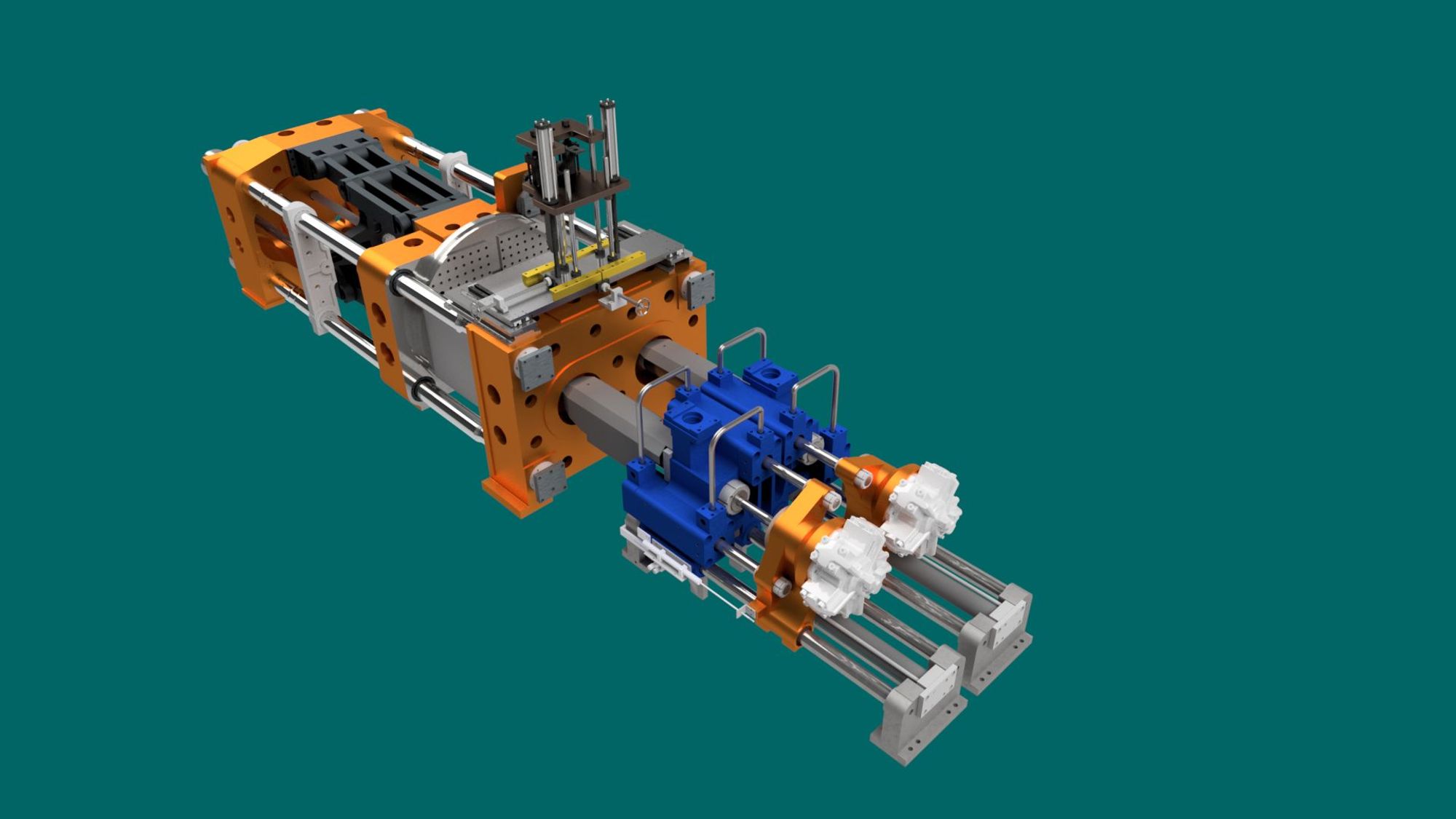

Multi injection

ー Diverse injection mode to suit your various product needs

When the production requirement for finished plastic products is two or more plastic materials.

The multi-injection unit can be customized according to the particular design of the mold. Examples of multi-injection types are as follows:

Double Injection

Parallel Double Injection

Front Injection + Side Injection

Front Injection + Vertical Injection

Mixed Injection + Side Injection

Mixed Injection + Vertical Injection

Tri Injection

Parallel Tri Injection

Parallel Double Injection + Side Injection

Parallel Double Injection + Vertical Injection

Front Injection + Vertical Injection + Side Injection

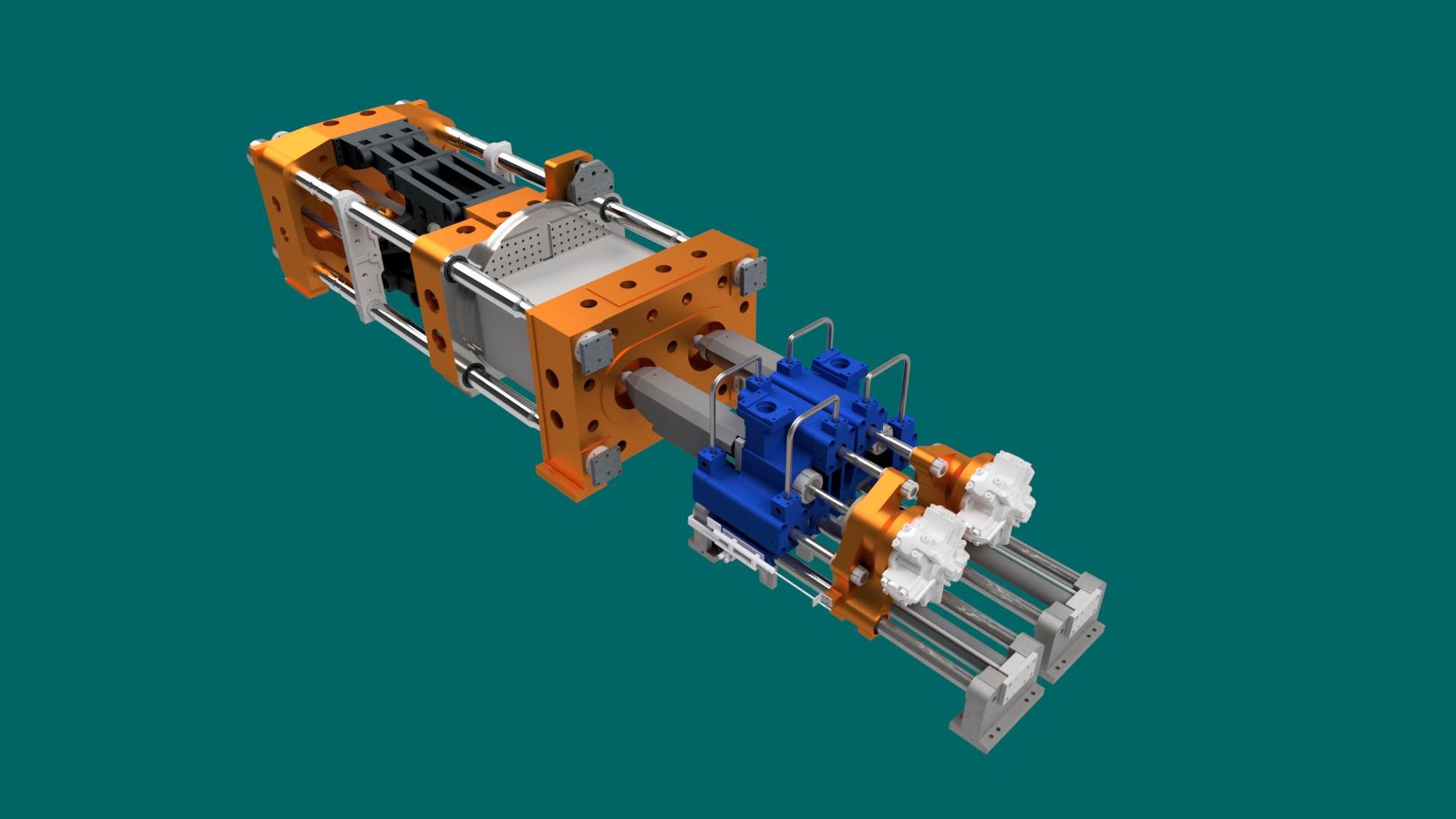

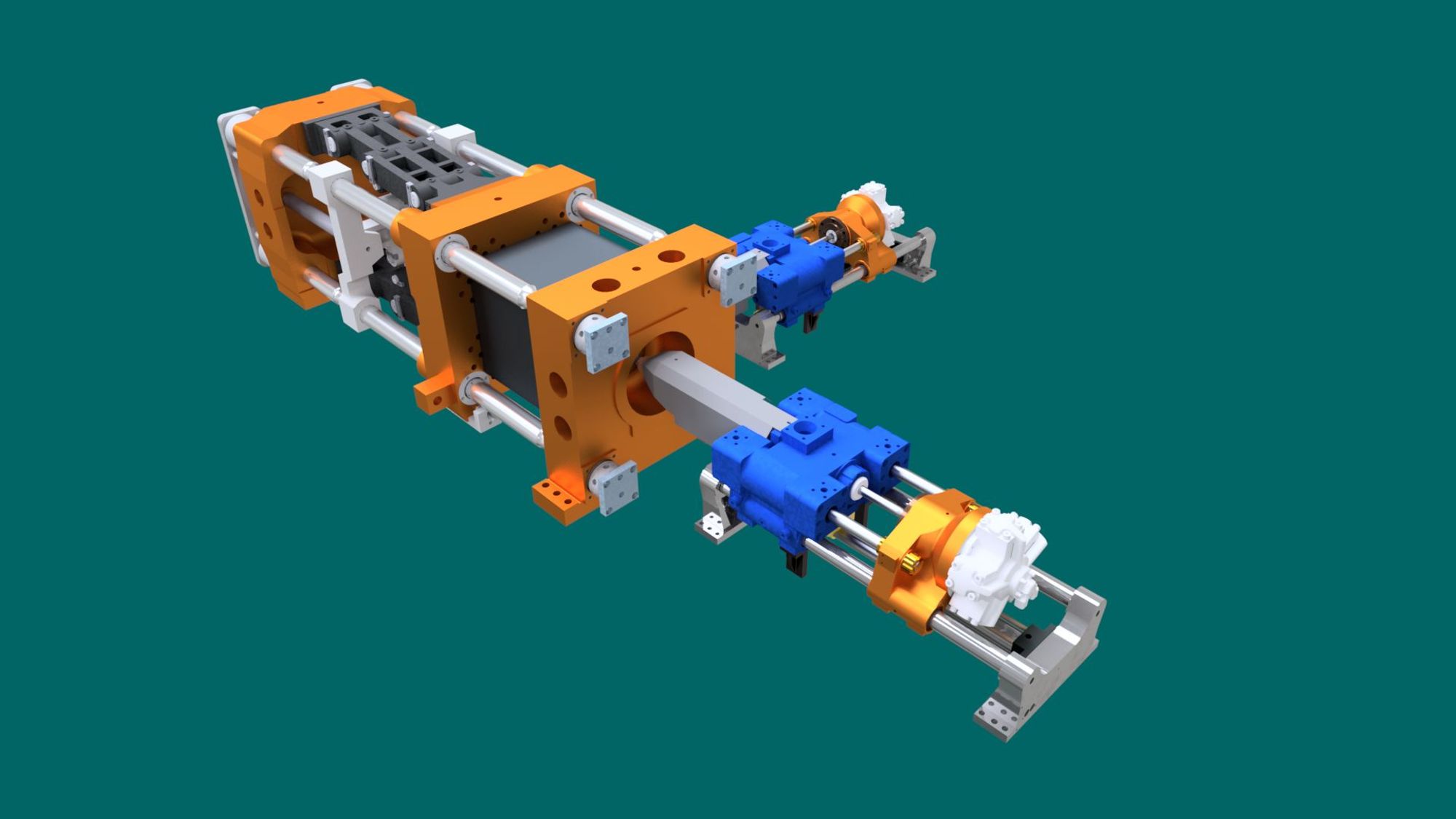

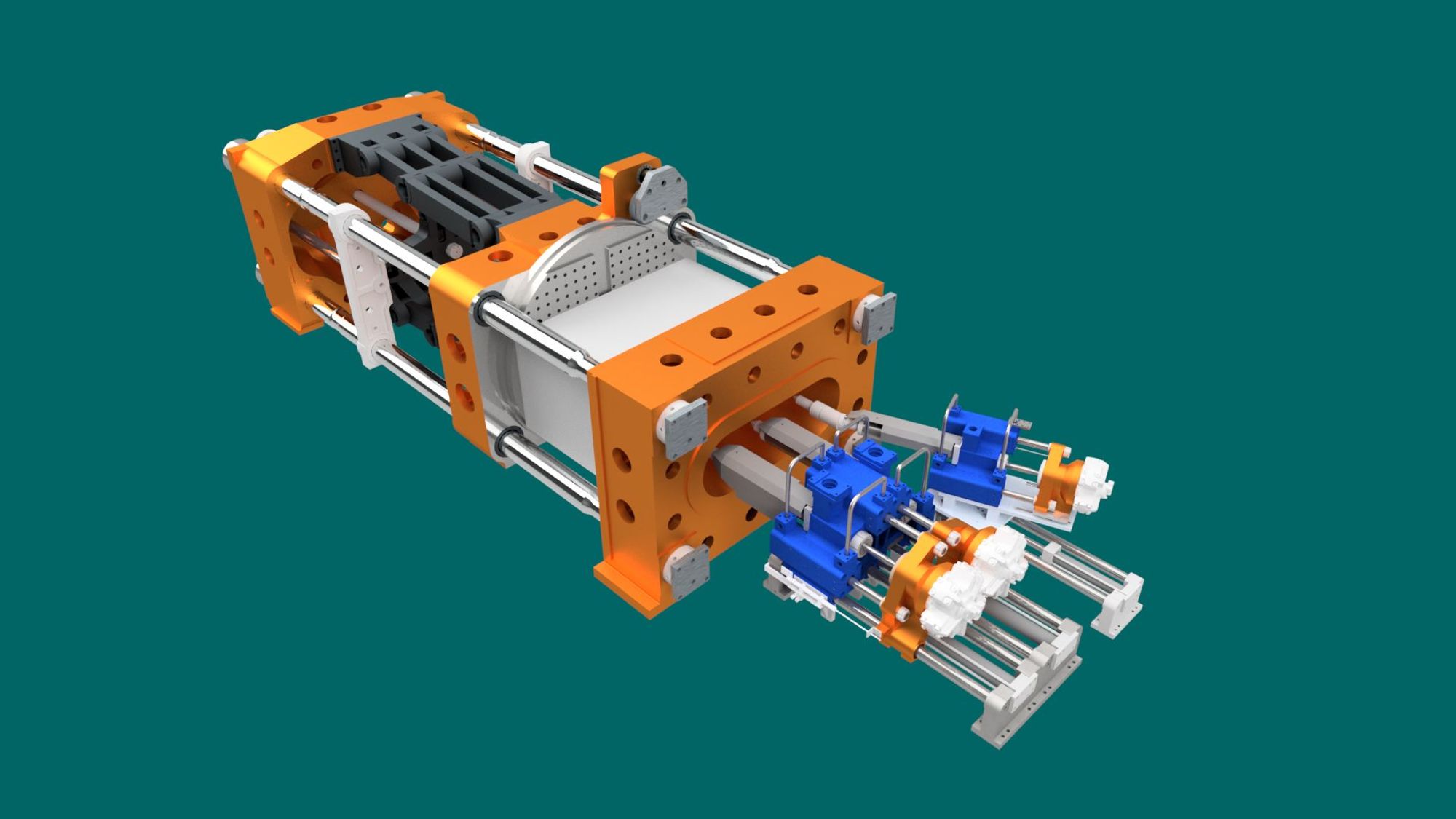

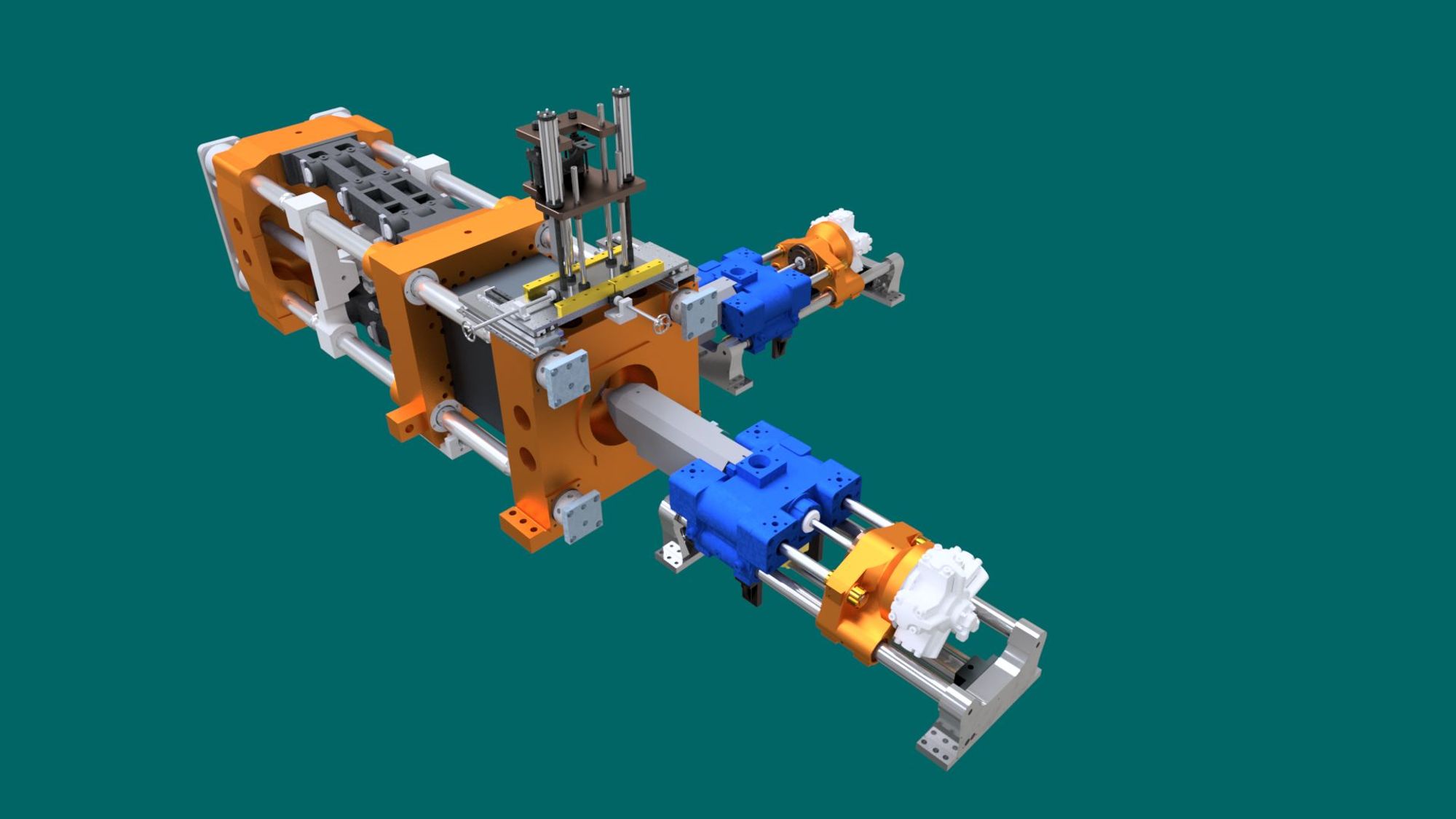

Energy-Efficient Direct Drive Material Storage Motor

ー Enhancing Storage Efficiency and Energy Performance, Ideal for Medium to Large Injection Molding Machines

The injection machine features a patented direct drive material storage servo motor (Patent No: M654645) capable of handling high axial and torque loads. This design eliminates the need for traditional hydraulic motors and gearboxes, creating a highly efficient, stable, and low-energy consumption production environment.

The direct drive material storage system offers a simpler transmission mechanism and more stable servo motor performance compared to similar products on the market, driving the material storage screw directly with a servo motor. This design addresses issues such as high torque requirements, costs, failure rates, and maintenance frequency associated with gear reducers, while also making the equipment more reliable and reducing maintenance frequency.

The direct drive material storage system reduces energy consumption by up to 26% during storage.

The storage system operates independently and can perform material storage concurrently with product cooling and mold opening, shortening the molding cycle and improving production efficiency.