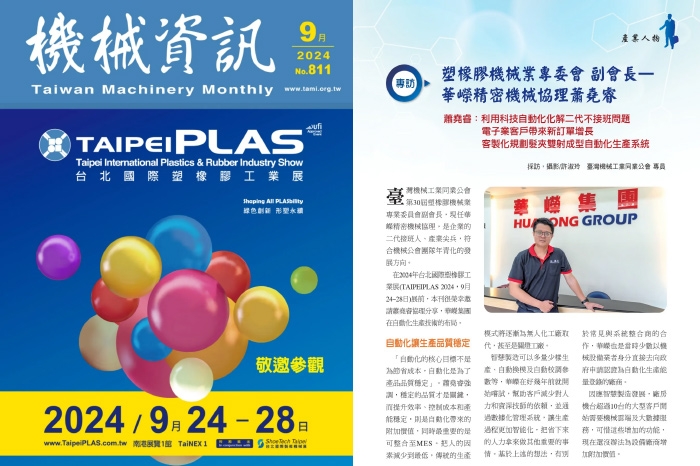

Interview: Vice Chairman of the Plastics and Rubber Machinery Committee – Huarong Plastic Machinery

2024-09-28 16:18:49

As the Vice Chairman of the 30th Plastics and Rubber Machinery Committee of the Taiwan Association of Machinery Industry (TAMI), Mr. Hsiao, Director of Huarong Plastic Machinery, is a second-generation successor who actively promotes automated production technologies, injecting new vitality into the industry.

Mr. Hsiao emphasized, "The core objective of automation is not to reduce costs but to stabilize product quality." He highlighted that while increased efficiency and cost control are added benefits, the real value of automation lies in consistent quality and reducing human errors by integrating with MES systems to realize unmanned and smart factories.

Huarong began laying the groundwork for smart manufacturing years ago, helping customers reduce their reliance on manual labor and optimize production processes through data management systems. This advanced technology positioned Huarong as one of the few machinery manufacturers directly certified by the government for automation production capabilities.

As Taiwan’s manufacturing sector enters the era of smart manufacturing, many companies face the challenge of succession. Mr. Hsiao noted that many second-generation successors are unfamiliar with traditional factory environments and lack an understanding of production parameters. However, with automation, successors can manage operations through data reports, allowing them to focus on market development and increasing their willingness to take over the business.

When discussing the value of technology, Mr. Hsiao emphasized, "Soft power is often underestimated, but it's something we need to strengthen." He explained that the true value of technology lies not only in the equipment itself but also in the ability to integrate and provide innovative solutions. Huarong established an automation division dedicated to design and development, with over 10 years of experience in electromechanical integration, focusing on providing non-standard and customized automation solutions, which have become a core competitive advantage for the company's continuous growth.

Huarong's global market performance is impressive, with strong demand from the electronics sector driving new order growth. Although some orders were paused during the pandemic, the rise of the stay-at-home economy and the global digitalization wave quickly restored Huarong's momentum. In the first half of 2024, Huarong's order volume increased by 20%, especially in emerging markets like Vietnam and the Philippines, where demand has been strong. In India, most orders were for automotive components, while the U.S. and Canadian markets also showed positive results.

At this year’s TAIPEIPLAS 2024, Huarong showcased its latest Hairclip Dual-Injection Molding Automation Production System, an integrated solution that combines injection molding, assembly, packaging, and transportation. This system features four equipments and four robot arms, achieving synchronized production across four molds, significantly boosting production efficiency.

This system demonstrates Huarong's technical expertise in automation integration, moving from plastic injection to packaged, shelf-ready products without any human intervention, embodying the essence of smart manufacturing. A distributor once commissioned Huarong to produce 400,000 hairpins, and using this system, Huarong not only completed the order efficiently but also maximized the value of production automation for the client.

The key to the Hairclip Dual-Injection Molding Automation Production System lies in the seamless connection between machines and the automation integration technology. While each piece of equipment can be purchased separately on the market, Huarong's integration skills enable the creation of a complete automated production line, differentiating the company from other suppliers.

In addition to the hairclip production system, Huarong also showcased other technological highlights, including two-platen and dual-injection molding machines, three vertical injection molding machines, and microcellular foam injection molding technology.

Regarding the global push toward plastic reduction policies, Mr. Hsiao believes the demand for plastic components will not decrease. Instead, the trend toward lightweight and reusable products will continue to grow. Huarong is committed to the development of energy-saving technologies and has implemented green energy measures within its factories, aligning with ESG development trends. He mentioned that by fully implementing the 5Rs—Reduce, Reuse, Recycle, Repair, and Refuse—waste reduction and resource recovery can be effectively achieved.

Since the official launch of Huarong's online marketing department, the company has already seen some success, particularly in cold-calling potential clients. The department currently focuses on customer relationship management and enhancing the company's image. For instance, the sale of Dry Molded Fiber machines in Europe came through digital cold-calling, with about ten units sold so far, making it one of the automated solutions cases. Although Mr. Hsiao acknowledges that the "human touch" remains irreplaceable in client relationships, he also admits that online marketing is an undeniable trend that is worth investing in for further development.

Previous news: Huarong Showcase 4 Innovative Breakthroughs in 7 Injection Molding Machines at TaipeiPlas 2024

Next news: Huarong’s Success at TaipeiPLAS 2024: A Step Toward Sustainable Innovation