Huarong’s Success at TaipeiPLAS 2024: A Step Toward Sustainable Innovation

2024-10-04 16:25:38

The TaipeiPLAS 2024 event was an exciting opportunity for Huarong to showcase its latest advancements in injection molding technology. At this prestigious event, we demonstrated our cutting-edge solutions and took the TaipeiPLAS Award, a significant recognition of our efforts toward sustainable innovation. The award emphasizes the principles of low carbon emissions, energy saving, and intelligent machinery, all areas where Huarong continues to make groundbreaking strides. This article will take you through the major events that marked our successful exhibition at TaipeiPLAS 2024 and our innovative technology.

Winning the 2024 TaipeiPLAS Award was undoubtedly the highlight of the exhibition. This prestigious accolade symbolizes Taiwan's dedication to innovation and excellence in the plastics and rubber industry, and Huarong was proud to be recognized for our efforts. The TaipeiPLAS Award focuses on developments in three core areas: low-carbon and energy-saving technologies, sustainable recycling, and smart machinery. This achievement reflects years of research and development to make injection molding machines more eco-friendly and efficient.

Receiving the TaipeiPLAS Award is more than just a trophy in our cabinet. It reaffirms our commitment to pushing the boundaries of what's possible in the field of injection molding. We firmly believe that innovation is the key to maintaining a competitive edge in international markets, and this award is a testament to our dedication.

In addition to winning the TaipeiPLAS Award, Huarong was honored to participate in the Plastic and Rubber Smart Machinery Forum, organized by the International Trade Administration under Taiwan’s Ministry of Economic Affairs. The forum focused on discussing the green and sustainable manufacturing practices critical to the future of the plastics industry. Being one of only four enterprises invited to this discussion underscores our role as a leader in the industry, particularly in advancing eco-friendly solutions.

In today’s rapidly changing world, the pressure to address global challenges like climate change and resource depletion has become more pressing. Companies now bear the dual responsibility of driving economic growth while actively participating in climate action to ensure a sustainable future. This is where ESG—Environmental Protection, Social Responsibility, and Corporate Governance—plays a pivotal role.

At Huarong, our commitment to sustainability and ESG principles goes beyond mere compliance. We have integrated these concepts into our operations through technological innovations to reduce carbon emissions, improve energy efficiency, and minimize waste. Our machines, including the Taiwan Excellence Award-Winning Smart Two-Platen Injection Molding Machine, are designed to boost productivity and decrease the environmental footprint. This machine's reduced size and innovations, like our patented direct-drive material storage system, demonstrate our focus on reducing space, material, and energy use, aligning with our sustainability goals.

Related product: Two Platen Injection Molding Machine – NRH Series

Further reading: HUARONG is honored with the 2024 Taiwan Excellence Award!

As a leading injection molding machine manufacturer, we’re not just developing more innovative machines; we’re shaping a future where resource-efficient and eco-friendly production processes are the new standard.

Huarong’s commitment to fostering innovation extends beyond our walls. At TaipeiPLAS 2024, we were proudly invited by PMC’s collaboration to welcome Taiwan’s elite universities and high schools, marking the first time students from these institutions were invited to experience the latest and realistic advancements in injection molding technology. This initiative highlights our belief that the next generation of engineers and R&D personnel will be pivotal in shaping the plastics industry's future.

We introduced students to our latest advancements in injection molding technology, showcasing the innovative equipment we presented at TaipeiPlas 2024. They were particularly impressed with the precision engineering and smart automation featured in our machines, designed to enhance energy efficiency and handle complex production tasks with minimal human intervention. These include our Smart Two-Platen Injection Molding Machine, Ultra-Energy Efficient Direct Drive Material Storage, Hairclip Double-Shot Automated Molding System, and Microcellular Foam Injection Molding Device.

For more detailed insights into these technologies, read our article: [Huarong Showcase 4 Innovative Breakthroughs in 7 Injection Molding Machines at TaipeiPlas 2024].

As Huarong Group moves forward, we remain focused on driving innovation in injection molding while staying committed to sustainable manufacturing. With over 40 years of expertise, we are constantly evolving our approach, incorporating cutting-edge technologies like smart automation, AI-driven optimization, and capabilities to work with recycled materials to meet the dynamic needs of our customers and the global market.

Our vision includes not just enhancing performance but also reducing the carbon footprint of our machines. Integrating energy-efficient motors and AI-powered monitoring systems empowers manufacturers to operate more sustainably without compromising efficiency or precision. We’re also committed to advancing circular economy principles, ensuring our equipment adapts seamlessly to recycled materials and aligns with the industry's growing focus on eco-friendly solutions.

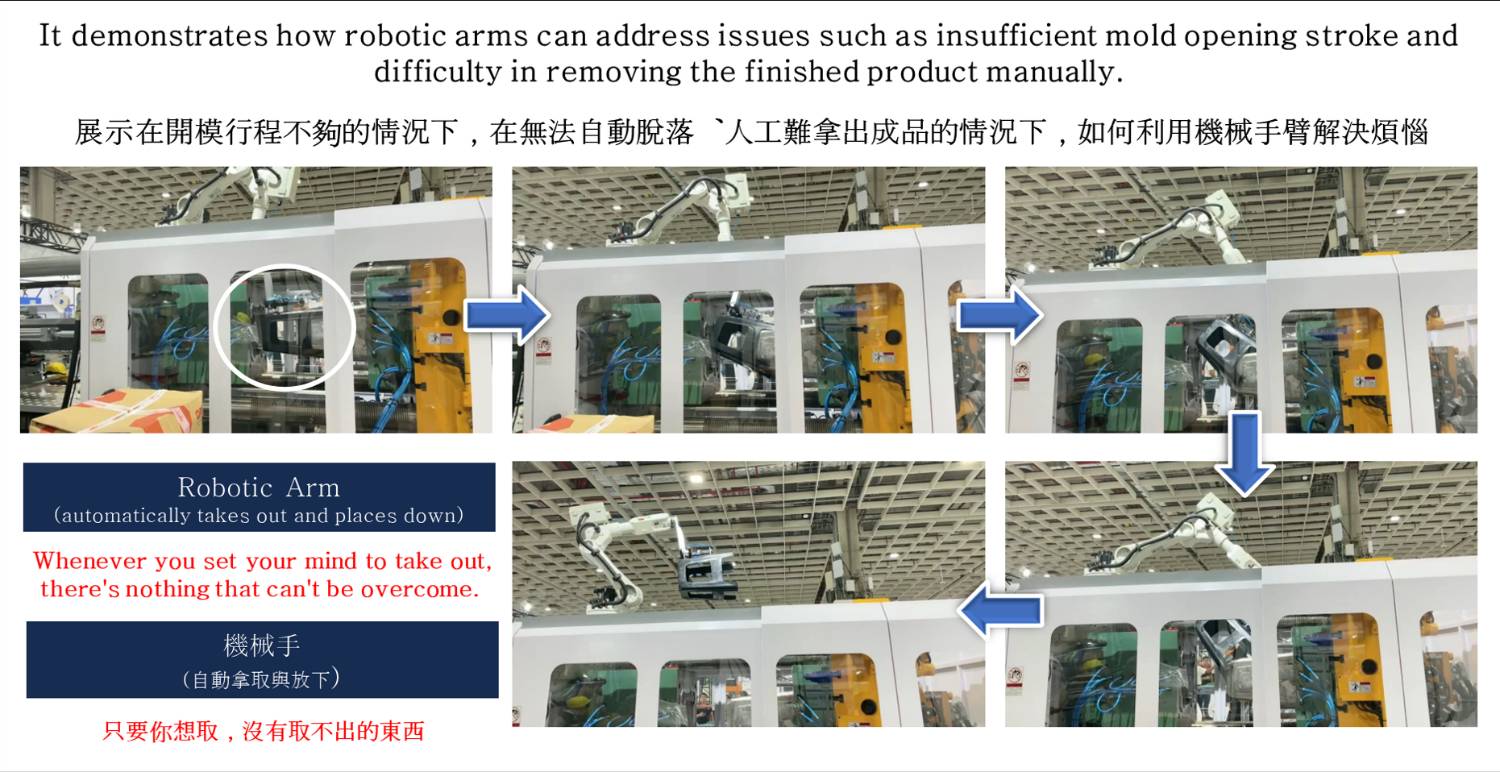

In the field of automation, we are expanding the role of injection molding robots in manufacturing. As fully automated production becomes the industry's future, Huarong has an independent automation department to assist with entire factory planning, such as product assembly, product inspection, and fully automated production. We continually improve these systems to ensure our customers enjoy shorter production cycles, higher productivity, and lower labor costs.

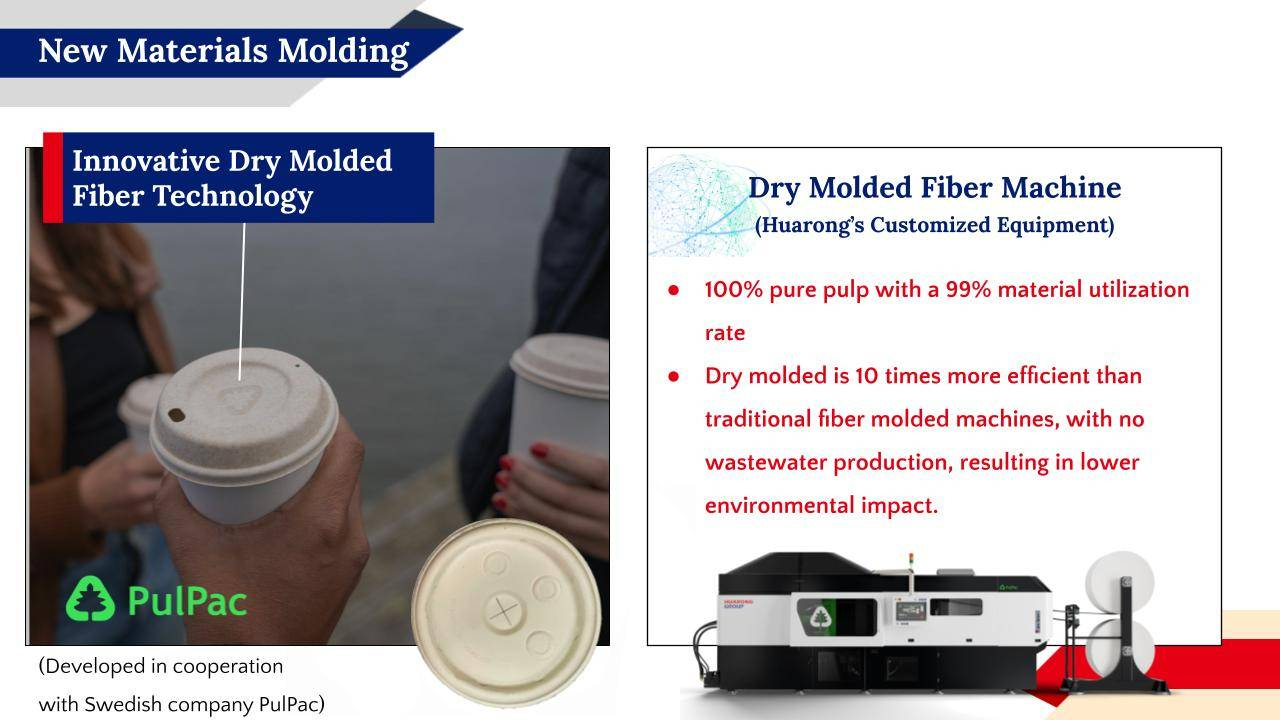

Looking ahead, Huarong is also entering the field of fiber molding through our collaboration with Pulpac, intending to provide eco-friendly alternatives to single-use plastics. Our Innovative Dry Molded Fiber Machine—which uses 100% pure pulp and produces zero wastewater—reflects our commitment to reducing environmental impact while offering efficient, sustainable solutions.

Pulpac's Dry Formed Fiber Technology: https://www.pulpac.com/dry-molded-fiber/

In everything we do, from standard injection molding machines to fully customized automation solutions, our goal is to be the best molding partner for our customers. As we continue to develop new technologies and lead with innovation, Huarong is committed to helping manufacturers succeed in a sustainable and ever-evolving industry.

TaipeiPLAS 2024 was a resounding success for Huarong, not only because of the awards and recognition but also because of the valuable connections and insights we gained. As we move forward, we remain dedicated to driving innovation in injection molding technology, focusing on sustainability and smart automation.

Our success at this year’s event reinforces our belief that the future of manufacturing lies in green technology and intelligent systems. Huarong will continue to provide manufacturers with the tools they need to thrive in a changing world. Every machine we build shapes a more sustainable, efficient, and intelligent future for the plastics and rubber industry.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : Interview: Vice Chairman of the Plastics and Rubber Machinery Committee – Huarong Plastic Machinery

Next news: Boosting Efficiency: NEOLITE ZKW's Success with Huarong's Injection Molding Machine