4 Core Innovations in Revolutionary Double-Shot Hairpins Automated Technology by Huarong

2024-10-22 17:18:37

When it comes to precision and efficiency, Huarong's double-shot hairpins automated technology stands at the forefront of innovation in injection molding. Our cutting-edge system is designed to transform the production process of hairpins, from raw materials to fully functional, non-slip products. This technology eliminates the need for manual intervention, ensuring that every step, from injection molding to packaging, is fully automated. In this article, we will take an in-depth look at the key technologies behind this breakthrough, showcasing not only the technical prowess of our machines but also Huarong's unmatched expertise in factory automation planning.

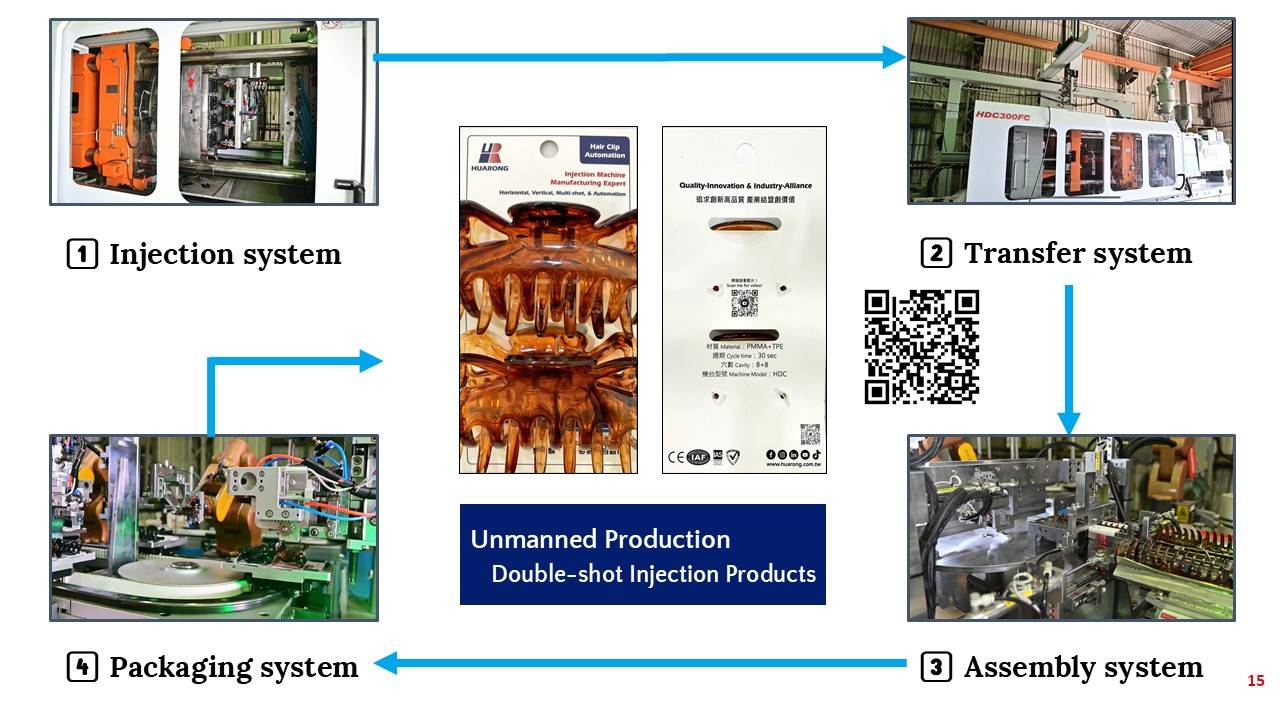

Huarong’s double-shot hairpins automated production system is an advanced integration of dual injection molding, transfer, assembly, and packaging technologies, creating a highly efficient, fully automated production line. This innovative solution is designed to meet the ever-growing demand for high-efficiency manufacturing while reducing labor costs, ensuring every step from injection molding to final packaging is seamlessly automated.

Several key factors drove the development of this technology:

The dual injection molding technology lies at the heart of this revolutionary technology. By simultaneously injecting two or more types of plastic in one cycle, which means that while one material is being injected, another is already prepared for the next step, the production cycle is significantly shortened. This technology ensures that different colors or materials are molded in sync, that the production lines become faster, that quality control is improved, and that we experience fewer defects, saving us time and resources. In addition, the multi-shot system allows for greater design flexibility. For example, the hairpin's non-slip feature is achieved using two different materials. One material provides the structural integrity of the pin, while the second, softer material ensures non-slip functionality. This would be near impossible to achieve with traditional, single-shot systems, reinforcing how multi-shot technology is a game-changer for injection molding.

Related product: Double Injection Molding Machine - HDC Series

To complement the multi-shot system, Huarong’s transfer technology combines injection molding robots, conveyors, and customized automation equipment to move parts from one station to another seamlessly. The transfer system's precision is critical in maintaining high productivity levels without compromising on quality, so the manipulator arms, in particular, play a significant role. They are programmed to handle irregularly shaped products carefully, avoiding potential damage during the transfer process and reducing labor costs while increasing output. Moreover, the smooth transition between stages enabled by the transfer system minimizes downtime, another critical factor in boosting the overall efficiency of the production line.

Related product: Injection Molding Robot / Manipulator Arm - HRB Series

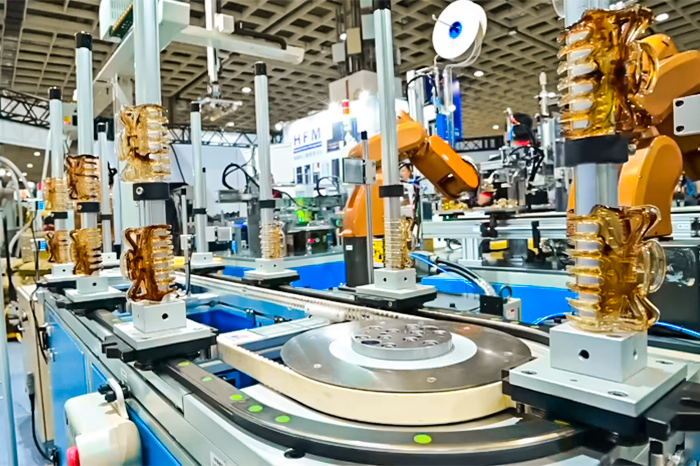

Next comes assembly technology, where the actual technical showcases to handle intricate assembly tasks that typically require skilled manual labor. The challenge with producing hairpins, particularly double-shot hairpins, lies in the assembly process. Transferring, positioning, clamping, and assembling irregularly shaped products like hairpins can be daunting. However, Huarong’s automated assembly system excels in overcoming these challenges. The assembly system efficiently combines two opposite hairpins, ensuring that each component is perfectly aligned before being secured and securing them with a torsion spring and pin. By automating this step, we reduce the possibility of human error and increase the speed at which the assembly takes place.

Further reading: Assembly Robots: The Evolution and Future of Robot Assembly Lines

For delivering a high-quality final product, it is crucial to ensure that the product is securely fastened in place, maintaining its quality during transport. Automating the packaging process eliminates inconsistencies and ensures that every product is packaged uniformly. Automated threading is significantly faster than manual packaging, allowing manufacturers to scale their operations without additional labor. Furthermore, it contributes to overall sustainability by precisely using packaging materials, minimizing excess, reducing material waste, leading to cost savings and a reduced environmental footprint—key factors for any manufacturer looking to meet modern sustainability standards.

- Injection Molding Machine|Huarong's HDC Series

- Produced Product | Plastic hairpins

- Injection Molding Material|PMMA+TPE

- Cavity | 8+8

- Goal|Unmanned production of dual-shot injection products

In conclusion, Huarong's double-shot hairpin automated technology is a prime example of how advanced injection molding technology can transform a production line. From the injection system that integrates multiple materials to the transfer, assembly, and packaging systems that streamline the entire process, this technology offers a comprehensive solution for hairpin manufacturers. Huarong's Assistant Manager Hsiao notes, “The core objective of automation is not just to reduce costs but to stabilize product quality.” He emphasizes that while improved efficiency and cost control are additional benefits, the valid key to automation lies in stable quality, reduced human error, and integration with MES systems, paving the way for unmanned smart factories of the future.

Further reading: Interview: Vice Chairman of the Plastics and Rubber Machinery Committee – Huarong Plastic Machinery

If you're considering investing in injection molding equipment or an automated solution, I highly recommend exploring Huarong. Huarong is an experienced injection molding machine manufacturer with complete equipment and service to help you find the best solution to improve efficiency and product quality. Contact Huarong to learn more about our automation technology and begin your journey toward the factory of the future!

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news: Boosting Efficiency: NEOLITE ZKW's Success with Huarong's Injection Molding Machine

Next news: PET Preform Molding Solution: A Detailed Guide to PET Preform Manufacturing