PET Preform Molding Solution: A Detailed Guide to PET Preform Manufacturing

2024-10-30 16:20:36

Many people ask Huarong questions about starting their PET preform manufacturing unit but are often unsure where to begin. Huarong, an experienced injection molding machine manufacturer, has crafted this comprehensive guide to the PET Preform Molding Solution to address these needs. This article covers every step of the preform production process to solve your related problems.

PET preforms are a vital intermediary step in bottle production, ensuring manufacturers achieve high-quality, lightweight, and durable containers. The demand for PET preforms stems from their durability, lightweight properties, and recyclability, making them ideal for packaging a wide range of beverages and products. As a reliable PET preform manufacturer, understanding these properties ensures optimal production efficiency and product quality.

What Is a PET Preform?

A PET preform is a test-tube-shaped initial product created from PET plastic, which is then expanded into bottles during the blow molding process. Preforms provide a standardized, quality-controlled step in bottle manufacturing, enabling consistent shapes, sizes, and weights in the final product. They can vary in weight, color, and shape depending on specific production requirements, making them versatile for different container applications.

Benefits of PET Preforms for Bottling Applications

PET preforms offer numerous advantages for bottling applications:

- Inventory Flexibility: Preforms can be produced, stored, and transported as needed, enabling better inventory management.

- Operational Efficiency: The two-step process, separating injection molding and blow molding, allows manufacturers to optimize operations for both stages.

- Material Cost Reduction: During reheating in the blow molding stage, bottle weight can be adjusted, significantly lowering material costs while maintaining quality.

- Environmental Sustainability: PET preforms contribute to eco-friendly practices by enabling lightweight and recyclable bottle production.

The PET preform molding process begins with preparing PET resin, which must be handled appropriately to ensure optimal molding results. Here is an in-depth look at each step of PET preform manufacturing:

Step 1: PET Resin Preparation and Drying

Drying PET resin is essential to ensure that the material is free from moisture, which can cause defects like cloudiness and brittleness. Advanced dehumidifying dryers are employed to set the stage for high-quality injection molding.

Step 2: Injection Molding for PET Preforms

In this step, dried PET resin is melted and injected into a preform mold. The injection molding process determines critical attributes like shape, weight, and wall thickness, ensuring consistent quality.

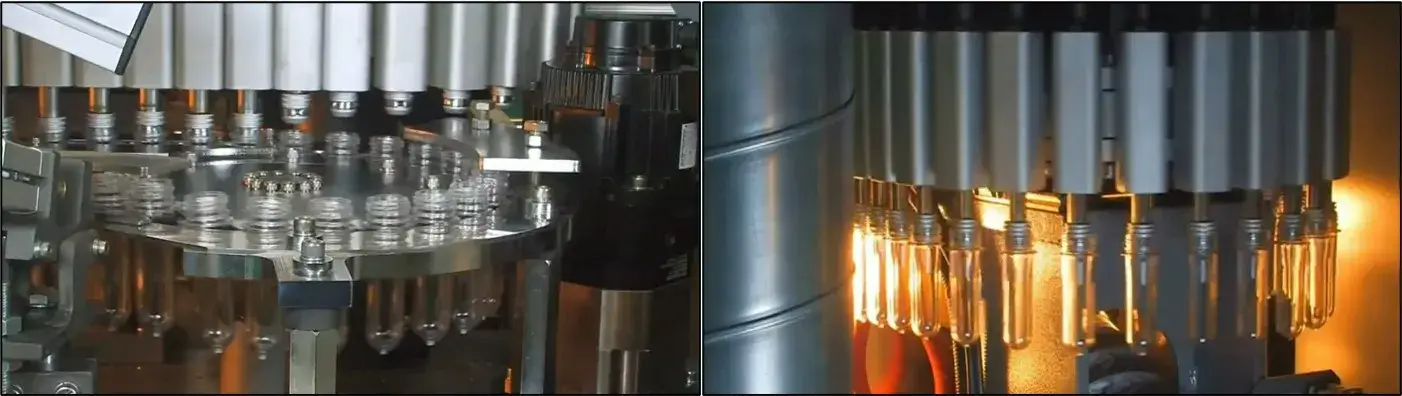

Step 3: Preform Cooling and Solidification

Rapid cooling is crucial to prevent defects such as dimensional inaccuracies and clarity issues. PET preforms are sensitive to temperature variations, making uniform cooling essential for achieving structural integrity and transparency.

Step 4: Quality Control in PET Preform Manufacturing

Quality control ensures that every preform meets precise specifications:

- Neck and Thread Inspection: Checks for defects like chips or scratches to ensure cap compatibility.

- Bottom Inspection: Identifies yellowing or scratches that may affect stability.

- Body Inspection: Ensures a smooth surface free of contaminants.

Producing high-quality PET preforms depends on specialized equipment designed to handle the demands of high-output manufacturing environments. With reliable machinery, the production of PET preforms becomes more efficient, minimizing issues that could compromise quality.

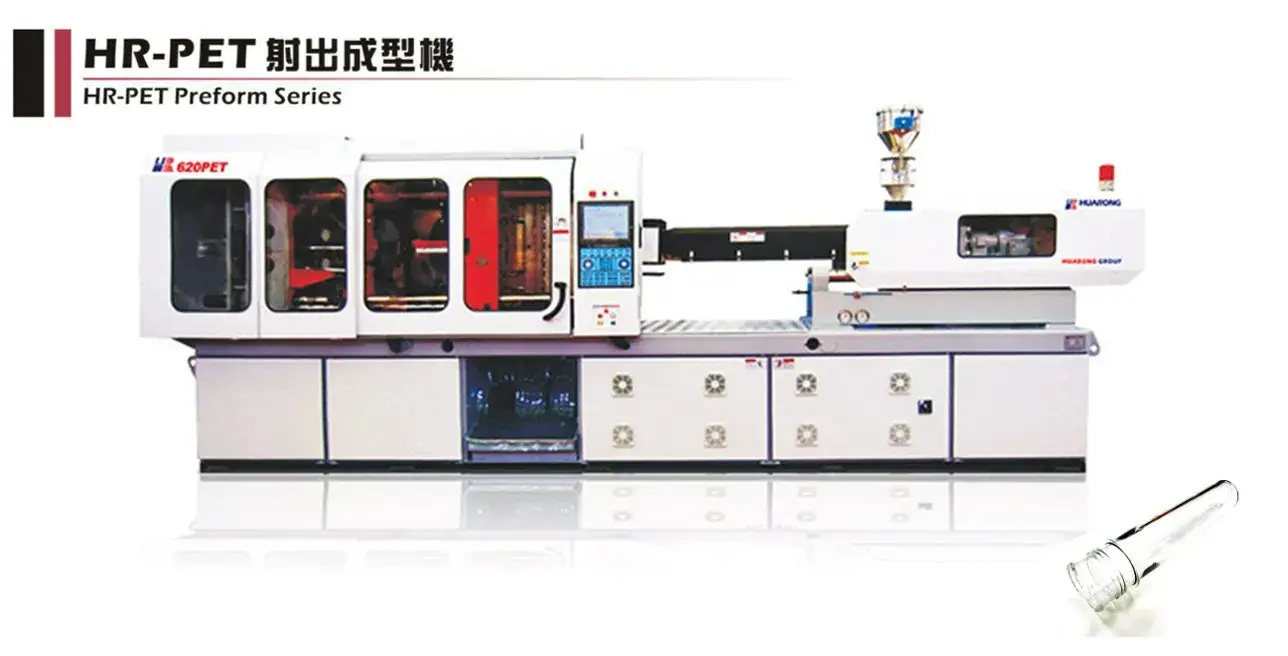

Injection Molding Machine for PET Preforms

At the core of the process, PET preform injection molding machines are designed for precision, efficiency, and consistency. Huarong’s machines are tailored to meet the rigorous demands of preform production.

Related product: PET Injection Molding Machine – PET Series

Essential Features for High-Performance PET Preform Production

- Enhanced Barrel and Screw Design for PET Materials

Feature a specialized PET-specific barrel and screw design that maximizes injection volume and feeding speed. With an increased screw diameter and Length-to-Diameter (L/D) ratio, that maintains stable material flow and minimizes cycle times. - Configurable Double-Circuit System for Optimized Cooling and Storage

Our machines will evaluate the customers’ production conditions to be equipped with a double-circuit system for simultaneous mold opening and material storage. This setup is especially advantageous for preforms with thinner walls, as the cooling time is shorter than the storage time. This system improves production efficiency and cycle consistency by initiating material storage while the mold is still cooling, resulting in a smoother workflow and higher productivity. - Optional Separate Injection and Plasticization Unit for Enhanced Stability

An optional separate unit can be installed for applications needing consistent plasticization. Isolating plasticization from injection enhances material quality stability. - Servo System

Combine the speed and power of hydraulic components with the precision of electric-driven systems to create a ideal for PET preforms. This setup delivers the necessary force for high-speed injection. - Enhanced Barrel and Screw Design: Optimized for PET materials, increasing injection volume and feeding speed.

- Double-Circuit System: Simultaneous mold opening and material storage, reducing cycle times and improving workflow.

- Separate Injection and Plasticization Units: Optional feature for consistent plasticization and enhanced material stability.

- Servo Systems: Combining hydraulic power with electric precision for high-speed, efficient operations.

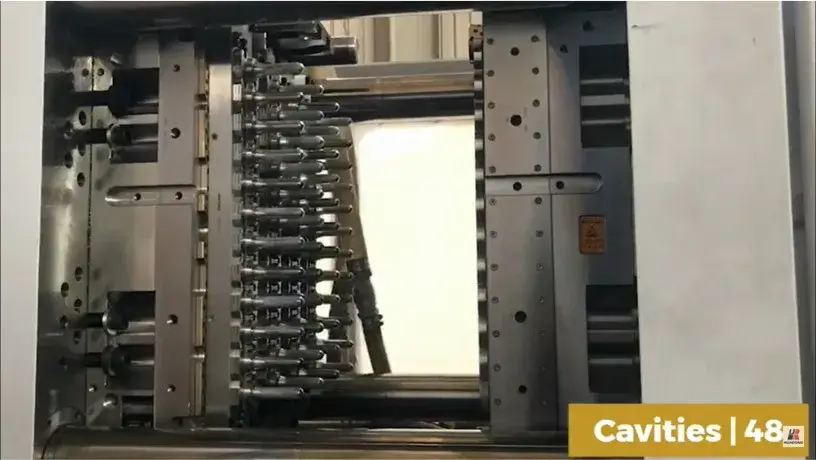

PET Preform Mold Design and Cavity Options

Mold design plays a pivotal role in achieving high-quality preforms. Key considerations include:

- Preform Dimensions and Neck Standards: Adhering to industry standards like PCO 1881 ensures compatibility with lightweight, high-volume production.

- Preform Weight and Wall Thickness: Critical for determining structural integrity and material efficiency.

- Cavity Count: Multi-cavity molds, such as 48, 72, or 96 cavities, maximize production rates without compromising quality.

Related production video: 48-Cavity Preform Production

Auxiliary Equipment in PET Preform Molding

Auxiliary equipment ensures consistent quality and efficient production. Key equipment includes:

- Dehumidifying Dryers: Removes moisture for stable feeding.

- Vacuum Automatic Feeding Systems: Ensures continuous material supply, reducing downtime.

- Mold Dehumidifiers: Maintains dry mold interiors to extend mold life.

- Chillers: Provides rapid cooling for precise temperature control.

Huarong’s approach involves tailoring machines to customer needs. Essential details include:

- Preform Information: Photos, dimensions, weight, and application specifics.

- Mold Information: Cavity count and dimensions.

- Production Goals: Target output rates guide machine configuration and auxiliary equipment selection.

When selecting a partner for PET preform production, a reliable and experienced solution provider makes a difference. With over 40 years of expertise, Huarong Group—which includes brands like Huarong, Yuhdak, and Nanrong—stands out as a trusted partner for injection molding solutions, offering a complete range of injection molding machines and automation systems. For inquiries on injection molding machines or complete automation solutions, Huarong Group is ready to be your dependable partner in injection molding.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : 4 Core Innovations in Revolutionary Double-Shot Hairpins Automated Technology by Huarong

Next news : Huarong Wins 2025 Taiwan Excellence Award for Innovative Injection Molding Technology