Huarong Wins 2025 Taiwan Excellence Award for Innovative Injection Molding Technology

2024-11-06 09:39:19

The 2025 Taiwan Excellence Award is a prestigious recognition of outstanding innovation, quality, and technological advancement. Huarong is excited to announce its victory in this esteemed category. This award underscores our commitment to pioneering advancements in injection molding technology that meet our customers' diverse needs. Read on to learn what distinguishes our latest award-winning machine and how it sets new standards in energy efficiency, intelligent manufacturing, and sustainable production.

Our team at Huarong is proud to receive the prestigious 2025 Taiwan Excellence Award. This honor reflects the innovative value and quality of our latest injection molding machine. Recognized by Taiwan's Ministry of Economic Affairs, the Taiwan Excellence Award is given to products that excel in four key areas: research and development, design, quality, and marketing. This award underscores our commitment to enhancing Taiwan's manufacturing sector and establishes our machine as a global benchmark for innovation.

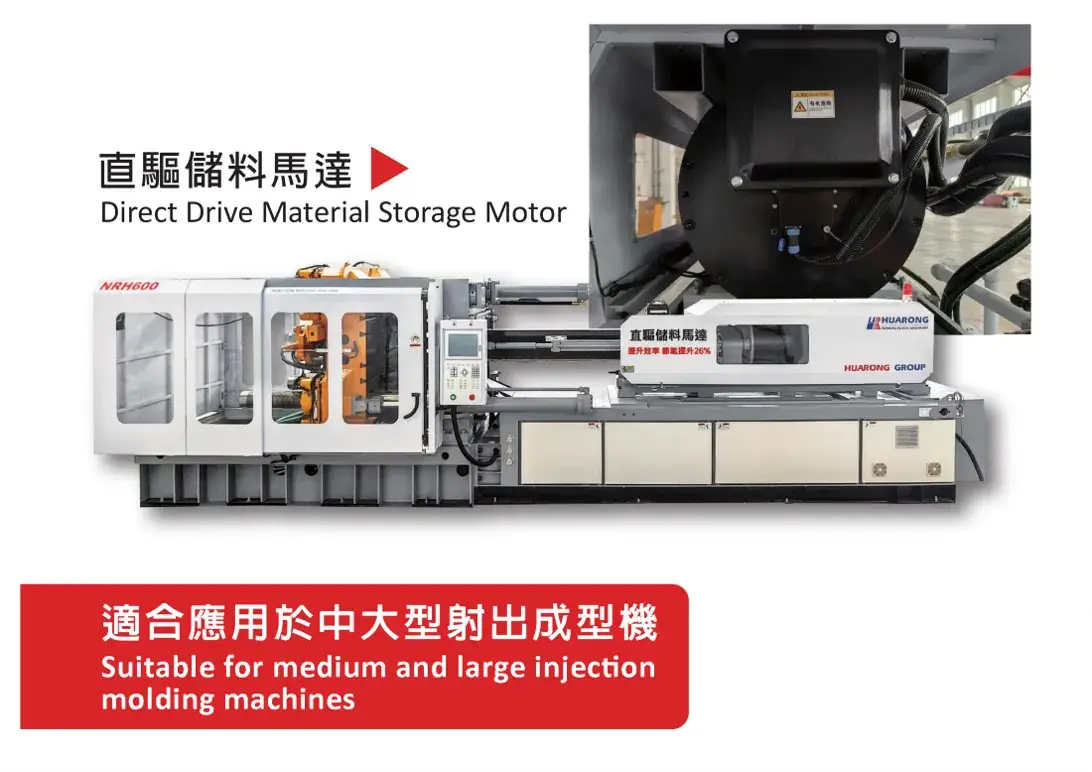

The award-winning injection molding machine is designed to meet high precision, reliability, and efficiency standards, aligning with the principles of sustainability and intelligent production that the award represents. This machine addresses current and future production needs with unmatched precision and efficiency by incorporating a groundbreaking direct drive material storage motor system and an advanced smart manufacturing platform. Below, we explore the unique features that differentiate this machine and demonstrate why it stands as a model of excellence in injection molding technology.

Pioneering Innovation and Engineering Excellence

Huarong’s award-winning machine embodies over four decades of engineering excellence and innovation. Since our founding in 1982, we have been dedicated to advancing injection molding technology through a sustained commitment to research and development, investing around 10% of our annual revenue to refine our machines and enhance the customer experience. Our dedication to quality is underscored by our ISO 9001/2015 certification, which guarantees that each step in our manufacturing process meets stringent international quality standards, as well as CE certification that assures compliance with critical European safety, health, and environmental protocols.

Unique Features that Drive Efficiency

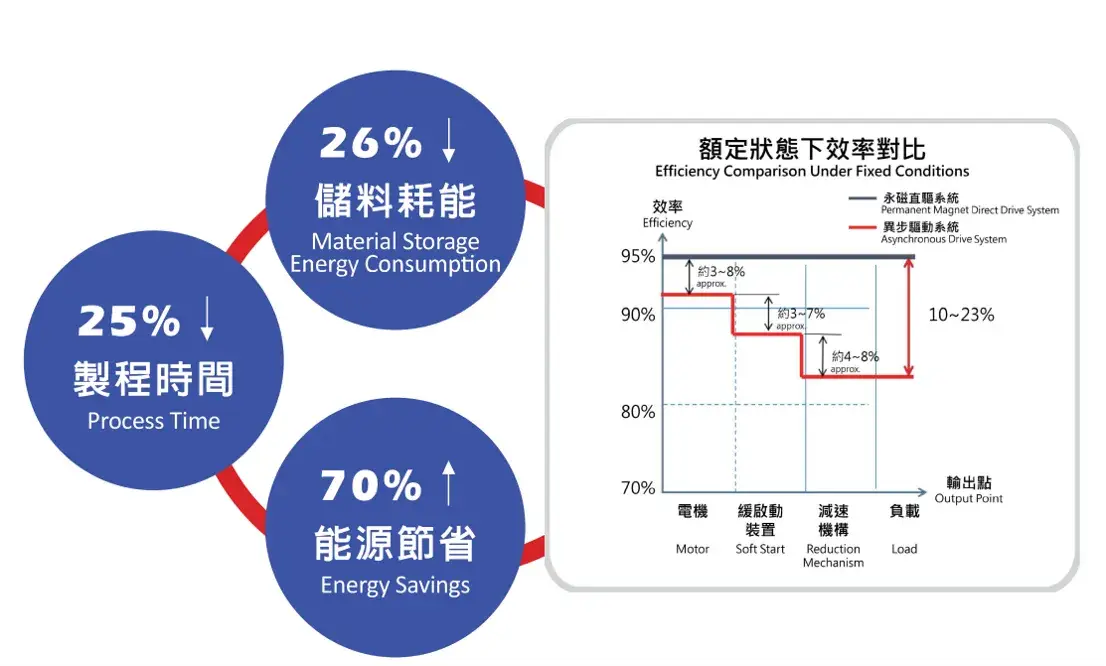

This machine's direct-drive material storage servo motor (Patent No: M654645) is a critical innovation designed with high axial and torque loads, setting it apart from conventional hydraulic motors and gearboxes. The direct-drive design simplifies the transmission structure, reducing mechanical wear and maintenance needs. With a torque rating of 7,003 Nm, this motor structure provides unmatched power while consuming significantly less energy.

Further reading: Injection Unit > Direct Drive Material Storage Motor

Additionally, our patented Suspension Bearing Module (M634662) minimizes energy loss caused by friction while preventing natural sagging of the tie-bar, thus maintaining precision and prolonging machine life. We’ve also integrated an Inner Sliding Module (M578643) and Injection Machine Positioning Device (M636571), enabling rapid assembly and positioning of sliding components, which bolsters the machine’s stability and accuracy.

Related product: Two-Platen Injection Molding Machine Obtained Patent Certification to Provide Better Machine

Huarong’s winning machine enhances production quality and aligns with modern sustainability goals. Compared to similar models, our machine conserves up to 26% of the energy used for material storage and saves up to 25% in production time. This commitment to sustainability extends throughout the product's lifecycle, from energy-efficient operation to recyclable materials in its injection molding machine components. This compact, energy-efficient design aligns with global green standards and ESG objectives, supporting sustainable manufacturing without compromising productivity or quality.

The 2025 Taiwan Excellence Award is a profound honor for Huarong, affirming our dedication to pioneering technology and innovative design in injection molding. This recognition underscores the value of our latest advancements and motivates us to continue enhancing our products. We are committed to creating injection molding solutions that are durable, efficient, and aligned with ESG principles, promising to meet the evolving needs of our customers and support a more sustainable industry.

If you're looking for advanced injection molding machines that offer precision, reliability, and environmental sustainability, Huarong is here to help. Please reach out to us to discover how our award-winning technology can enhance your production capabilities. Let us partner with you on the journey toward a more innovative and sustainable manufacturing future.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : PET Preform Molding Solution: A Detailed Guide to PET Preform Manufacturing

Next news : Microcellular Foam Injection Molding: Achieving Maximum Weight Reduction and Dimensional Stability