Custom Injection Molding Machine Services | Precision Manufacturing Solutions

2024-12-06 17:10:05

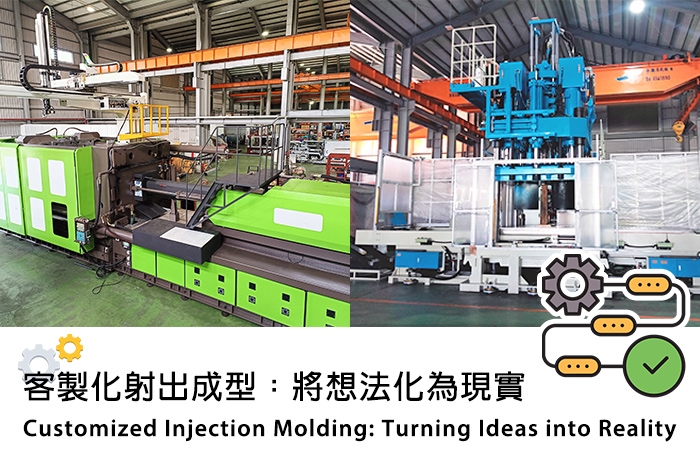

Precision and efficiency are paramount to success in today's fast-paced manufacturing landscape. Custom injection molding machine services have revolutionized how industries meet complex design and production needs, offering tailor-made solutions for everything from automotive components to medical devices.

This introduction page delves deep into the applications, technologies, and bts of custom injection molding machine services, showcasing how innovative providers like Huar. It showcases businesses that can transform ideas into tangible products through precision engineering and cutting-edge technology.

Custom injection molding is a specialized manufacturing process that produces intricate, high-quality components that meet precise design requirements. By leveraging advanced technologies, custom injection molding machines adapt to specific industry needs, enabling manufacturers to achieve complex geometries, tight tolerances, and enhanced production efficiency.

Huarong’s Expertise in Custom Injection Molding

Huarong is a leading name in the injection molding industry, known for its cutting-edge solutions such as the 450-ton vertical injection molding machine designed for automotive glass edge encapsulation. These solutions highlight the company’s ability to meet even the most challenging production requirements while maintaining exceptional quality.

Customers need customized equipment for automated, unmanned factories, especially for large, precise components. Integrating advanced features like in-mold monitoring, closed-loop systems, and centralized control ensures accuracy and efficiency. Custom injection molding machines are essential due to their multi-functional capabilities, exceptional injection precision, and optimized floor space—making them ideal for producing complex, high-quality products.

Key Features of Huarong’s 450-Ton Vertical Model

- Precision Compensation Mechanism: Handles tolerances of ±0.2mm to ensure that sensitive components, like automotive glass, remain intact during molding.

- Fully Automated Production: Reduces workforce demands, transforming a 10-person production line into an unmanned operation, driving significant cost savings.

- Flexible Configurations: Adaptable designs, including vertical-clamp-horizontal-injection and dual-clamp-single-injection, to cater to various production requirements.

- High-Capacity Performance: Delivers double the output of standard machines while requiring minimal floor space.

- Consistent Manufacturing Quality: Achieves weight variances of just ±1g for every 1,000g, ensuring exceptional precision and product consistency.

Investing in custom injection molding machine services offers transformative benefits for manufacturers:

Unmatched Precision

Custom machines meet stringent tolerances, enabling the production of intricate components with exceptional accuracy.

Enhanced Flexibility

From vertical to horizontal configurations, custom machines adapt to diverse applications across industries, including automotive, medical, packaging, and consumer goods.

Optimized Efficiency

Full automation, integrated robotics, and smart systems reduce cycle times, streamline operations, and lower labor costs.

Sustainability and Waste Reduction

Modern machines incorporate eco-friendly designs, maximizing material use and minimizing environmental impact.

Cost Savings in the Long Run

While initial investment may be high, custom machines reduce long-term production costs by enhancing efficiency and minimizing downtime.

Huarong’s custom injection molding process is a seamless journey that turns client ideas into manufacturing solutions:

- Requirement Analysis and Ideation: Collaborating with clients to identify needs and challenges.

- Design and Prototyping: Using 3D modeling and functional testing to refine product designs.

- Custom Machine Fabrication: Tailoring machine designs to align with client-specific production goals.

- Quality Assurance and Testing: Conducting rigorous tests to ensure stability and precision in production.

- Mass Production and Delivery: Implementing fully optimized manufacturing systems for large-scale production.

Diverse Injection Molding Services for Every Need

- Horizontal Injection Machines: Hydraulic and servo models allow clamping forces ranging from 60 tons to 5,000 tons and above.

Related product: Injection Molding Machines Overview - Vertical Injection Machines: Clamping forces from 15 tons to 450 tons and above, with customizable mold clamping designs tailored to client needs.

Related product: Vertical Injection Machines Overview - Automation Systems: Full automation—material feeding, molding, assembly, and packaging—reduces labor costs.

Further reading: Comprehensive Guide to Injection Molding Robots: Automate Your Production Process - Smart Factory Management Systems: Proactively predicts potential issues for uninterrupted operations.

Further reading: Huarong got certification of Automatic intelligent system

Huarong's custom injection molding technology is widely applied across automotive, medical devices, and packaging industries. Below are some notable examples:

Automotive Glass Edge Encapsulation - Case 1

An American automotive glass manufacturer partnered with Huarong to produce high-tolerance glass components using the 450-ton vertical injection molding machine. The result? Successful contracts with premium brands like BMW, Benz, and Tesla are driven by superior precision and efficiency.

Automated Hair Clip Production - Case 2

Huarong’s dual injection molding technology enabled the mass production of precision hair clips. By integrating molding, assembly, and packaging, the process achieved a seamless balance of functionality and aesthetics while reducing production costs.

Custom injection molding machine services are highly versatile, serving industries such as:

- Automotive: Producing durable, lightweight components like dashboards and bumpers.

- Medical Devices: Manufacturing sterile, precise components such as syringes and surgical tools.

- Consumer Goods: Creating aesthetically pleasing and functional products for everyday use.

- Packaging: Ensuring high-quality, sustainable solutions for food and beverage containers.

Huarong, as an experienced injection molding machine manufacturer, stands out in the competitive landscape of injection molding for its:

- Technological Innovation: Offering advanced solutions like the 450-ton vertical machine for demanding applications.

- Comprehensive Support: From R&D to after-sales services, Huarong ensures seamless client experiences.

- Global Presence: With support across Asia, Africa, and the Americas, Huarong delivers localized expertise tailored to market needs.

Custom injection molding machine services are the cornerstone of modern manufacturing innovation, enabling businesses to tackle complex challenges with precision and efficiency. Whether it’s achieving tight tolerances, scaling up production, or reducing environmental impact, providers like Huarong are redefining possibilities for industries worldwide.

Contact Huarong

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : Plastic Bottle Cap Manufacturing: Injection Molding Technology and Applications

Next news : Multi-Injection Molding: A Deep Dive into Configurations and Applications