Huarong's Vision for 2025: Shaping a Sustainable Future in Injection Molding Technology

2025-01-03 09:28:16

As we enter 2025, Huarong reflects on its 40+ years of excellence in injection molding technology while embracing a future driven by innovation and sustainability. This year marks a pivotal moment in our journey as we align our goals with global environmental priorities, push the boundaries of technological advancement, and strengthen our commitment to empowering our customers.

At Huarong, sustainability is not just a goal—it’s our responsibility. We are actively developing technologies that support environmentally friendly manufacturing practices and help our customers reduce their environmental impact.

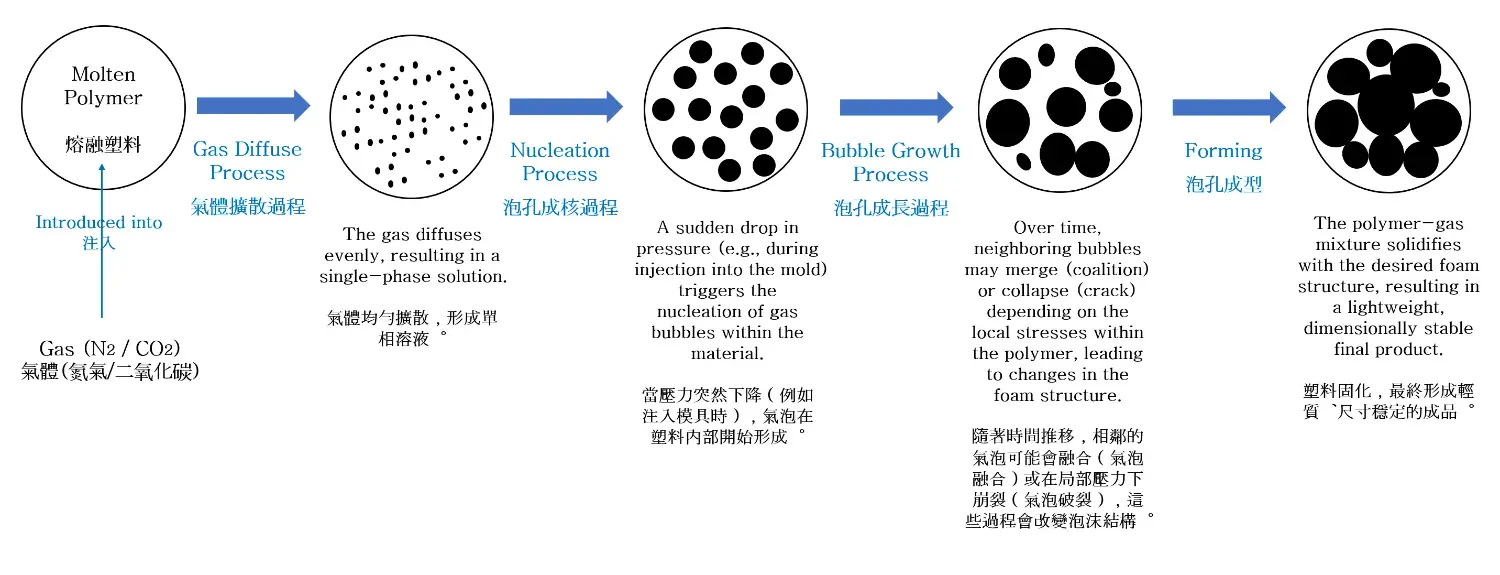

Microcellular Foam Injection Molding Technology

This technology precisely controls supercritical fluid injection into molten plastic to form a uniformly distributed microcellular structure. It significantly reduces material usage while maintaining the product's strength and quality. This enables the production of lightweight and resource-efficient components, minimizing raw material consumption and waste generation.

Further reading: Microcellular Foam Injection Molding: Achieving Maximum Weight Reduction and Dimensional Stability

Related feature: Microcellular Foam Injection Molding Technology

Energy-Efficient Direct Drive Material Storage Motor

Eliminating the traditional design of hydraulic motors and gearboxes, this innovative design uses a servo motor to drive the material storage screw directly. It can withstand the high axial and torque loads generated during the process, streamlining the servo motor transmission structure. This results in a highly efficient, stable, and energy-saving production environment.

Related feature: Energy-Efficient Direct Drive Material Storage Motor

Servo Motor Technology

Huarong is an industry pioneer in integrating servo motor technology into hydraulic injection molding machines, setting a new benchmark for improving energy efficiency and operational precision. This innovation combines the precise energy control of electric motors with the robust stability of hydraulic systems, redefining performance standards in injection molding technology. Its key advantages include:

- Precise energy control, tailoring energy output to production demands.

- Enhanced energy efficiency, significantly reducing power usage compared to traditional hydraulic systems.

- Greater flexibility and durability make it suitable for a wide range of applications.

Related feature: Servo system

These technologies reflect our dedication to ESG principles and leadership in promoting sustainable practices across the injection molding industry.

In 2025, Huarong remains at the forefront of technological innovation, addressing the evolving needs of our customers and the market:

Smart Manufacturing Solutions

Machines like our Two-Platen Smart Injection Molding Machine, recognized by the 2024 Taiwan Excellence Award, showcase our integration of Industry 4.0, IoT connectivity, and real-time monitoring to enhance efficiency and productivity.

Related product: Two platen injection molding machine – NRH series

Related product: Smart Factory Management

Related reading: HUARONG is honored with the 2024 Taiwan Excellence Award!

Understanding that no two customers are alike, Huarong prioritizes personalized solutions that maximize value for each client.

Customized Injection Molding Machines Solutions

Huarong is dedicated to fulfilling customer needs by designing and manufacturing customized injection molding machines. These machines are tailored to meet specific requirements, enabling operational success and enhancing production efficiency, setting them apart from standardized designs in the market. We create bespoke machines that perfectly align with our clients' unique demands. The key features of our customized injection molding machine solutions include:

- Comprehensive Custom Design: We can start from scratch and redesign the machine's structure and functions based on customer needs, ensuring it perfectly fits specific application scenarios.

- Versatile Application Scenarios: Whether it’s multi-material multi injection molding, in-mold labeling for packaging, or other complex manufacturing processes, our machines achieve high precision and handle even the most challenging production tasks.

- Integration of Innovative Technologies: Our machines can incorporate cutting-edge technologies such as IoT-enabled intelligent monitoring systems and AI-driven production analytics, effortlessly empowering customers to adapt to intelligent manufacturing trends.

- Long-Term Scalability: Our designs address current needs and consider potential future expansions, ensuring that customers maintain a competitive edge in an ever-changing market.

- Maximized Customer Value: By working closely with our clients, we provide more than just products—we deliver solutions that ensure each injection molding machine maximizes the customer's production goals.

Further reading: Custom Injection Molding Machine Services | Precision Manufacturing Solutions

Customized Factory Automation Solutions

From concept to completion, we work closely with our customers to design fully customized automation systems that meet their specific production goals and challenges. We help clients achieve higher productivity and lower operational costs. Highlights include:

- End-to-End Automation: We design systems that handle every production stage, from material handling and injection molding to assembly and packaging, eliminating the need for manual intervention.

- Application-Specific Designs: Our automation solutions are fine-tuned to meet exacting industry standards and requirements in industries such as automotive, medical devices, and consumer goods.

- Smart Factory Integration: Our systems, with advanced IoT and AI capabilities, enable real-time monitoring, predictive maintenance, and data-driven decision-making for optimal performance.

Related reading: Assembly Robots: The Evolution and Future of Robot Assembly Lines

Related reading: 4 Core Innovations in Revolutionary Double-Shot Hairpins Automated Technology by Huarong

2025 represents a new year and a renewed commitment to excellence, innovation, and sustainability. Winning the 2025 Taiwan Excellence Award is a testament to our hard work and dedication to pushing the boundaries of injection molding technology.

Your Insights Matter: Help Us Improve for 2025

As we embark on a new year, we want to take a moment to thank you—our valued customers—for your trust and support throughout 2024. Your partnership drives us to continuously innovate and improve, ensuring that Huarong delivers exceptional injection molding machines and outstanding service and support.

We would greatly appreciate your feedback to help us better serve you in 2025. We’re eager to hear your thoughts on:

- Machine Performance

- After-Sales Service

- Sales Support

A Warm Wish for the New Year

As we welcome 2025, we extend our heartfelt wishes to you and your team. May this year bring you abundant success, growth, and opportunities. We look forward to working with you to achieve even more significant milestones together. Thank you for choosing Huarong as your trusted partner, and may the year ahead be filled with prosperity and innovation for us all.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : Reflecting on a Year of Innovation and Excellence: Huarong's 2024 Overview

Next news : Injection Molding Defects: Causes and Solutions