Thermoset Injection Molding: Process, Benefits & Applications

2025-02-14 10:02:57

Thermoset injection molding is a specialized manufacturing process that utilizes thermosetting plastics to produce high-precision, durable, and heat-resistant parts. This article will explore the thermoset injection molding’s key advantages, materials used, applications, and how it compares to thermoplastic molding.

Thermoset injection molding involves using heat and pressure to shape thermosetting plastics into complex components. Unlike thermoplastics, which can be reheated and reformed, thermosets form permanent cross-linked molecular structures upon curing, making them rigid and heat-resistant.

Key Properties of Thermoset Plastics:

- High heat resistance – Maintains structure under extreme temperatures.

- Excellent mechanical strength – Ideal for structural applications.

- Electrical insulation – Used in electrical and electronic components.

- Chemical resistance – Suitable for industrial and automotive use.

Further reading for non-thermoset plastics: Understanding the 10 Most Common Injection Molding Materials

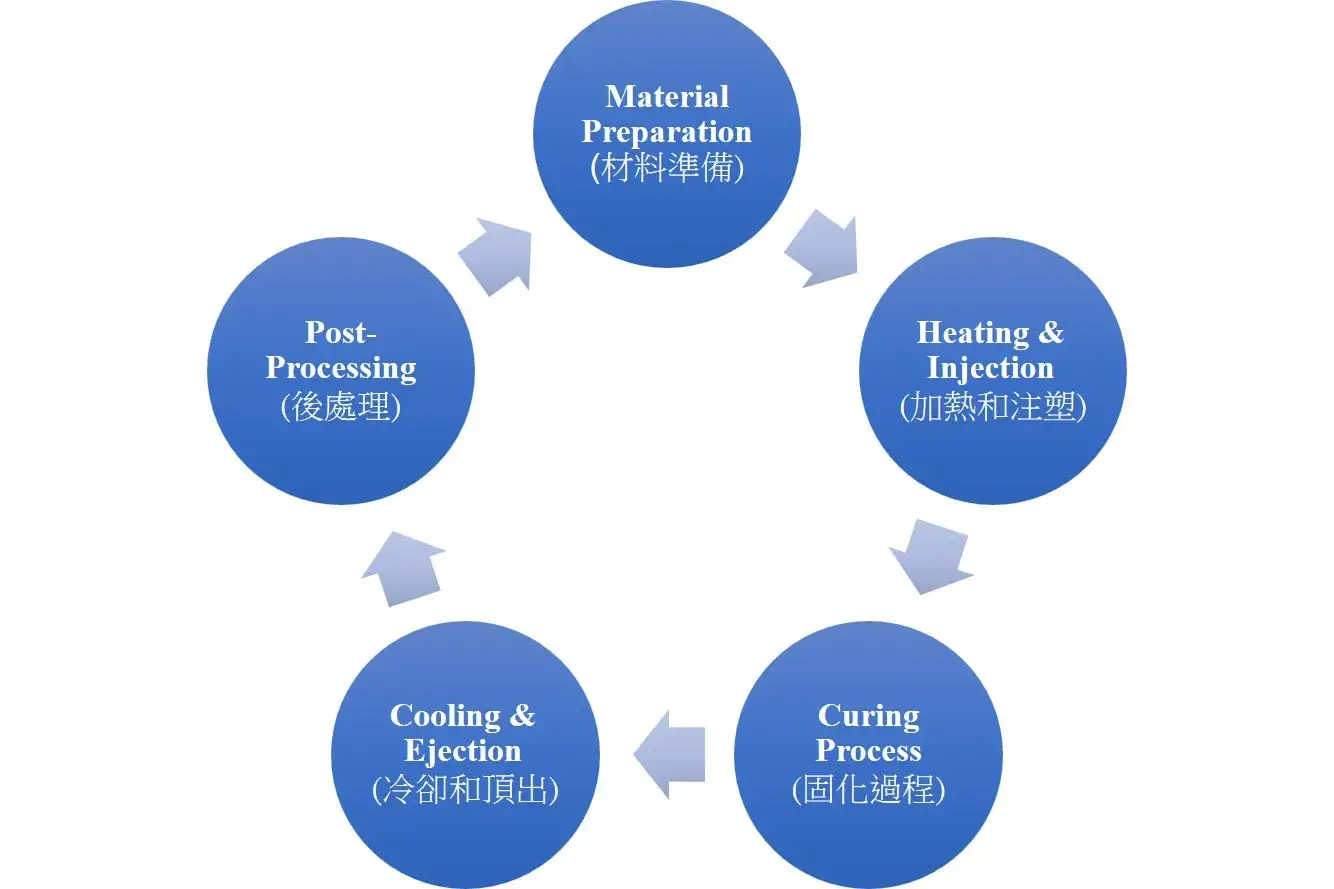

- Material Preparation: Thermosetting polymers are fed into the injection molding machine, usually in granular or preform form.

- Heating & Injection: The material is heated and injected into a preheated mold under high pressure. Unlike thermoplastics, thermosets do not melt; they are softened enough to flow into the mold.

- Curing Process: Heat and pressure trigger a chemical reaction (cross-linking) that solidifies the material into its final shape. This irreversible step means the material cannot be reshaped or remolded.

- Cooling & Ejection: After the curing process, the part is cooled and ejected from the mold.

- Post-Processing: Some parts may require additional finishing, such as trimming excess material, surface treatment, or coating.

Further reading for non-thermoset injection molding process: What is Injection Molding? Processes, Benefits, and Applications

Thermoset injection molding relies on high-performance materials designed for durability, heat resistance, and electrical insulation. The most commonly used materials include:

- Bulk Molding Compound (BMC)

- Key Properties: High rigidity, heat resistance, electrical insulation

- Applications: Automotive parts, electrical housings, industrial equipment

- Liquid Silicone Rubber (LSR)

- Key Properties: Flexible, biocompatible, temperature-resistant

- Applications: Medical devices, automotive seals, electronics

- Phenolic Molding Compound (PMC, Bakelite)

- Key Properties: Excellent electrical insulation, high heat resistance, strong mechanical stability

- Applications: Electrical insulators, automotive components, and appliance handles

- Diallyl Phthalate (DAP)

- Key Properties: Superior dielectric strength, moisture-resistant

- Applications: Aerospace, industrial, and electrical components

Related product: Bulk Molding Compound/BMC Injection Machine - HMC Series

Related product: Thermosetting Bakelite Injection Machine - BL Series

- High Heat Resistance: Thermoset materials can withstand extreme temperatures without deforming, making them ideal for electrical and automotive applications.

- Excellent Mechanical Strength: Once cured, thermoset plastics have high tensile strength, rigidity, and resistance to wear and tear.

- Chemical & Corrosion Resistance: Unlike thermoplastics, thermosets resist harsh chemicals, making them suitable for industrial applications.

- Dimensional Stability: Thermoset materials do not warp or deform under mechanical stress, ensuring consistent part accuracy.

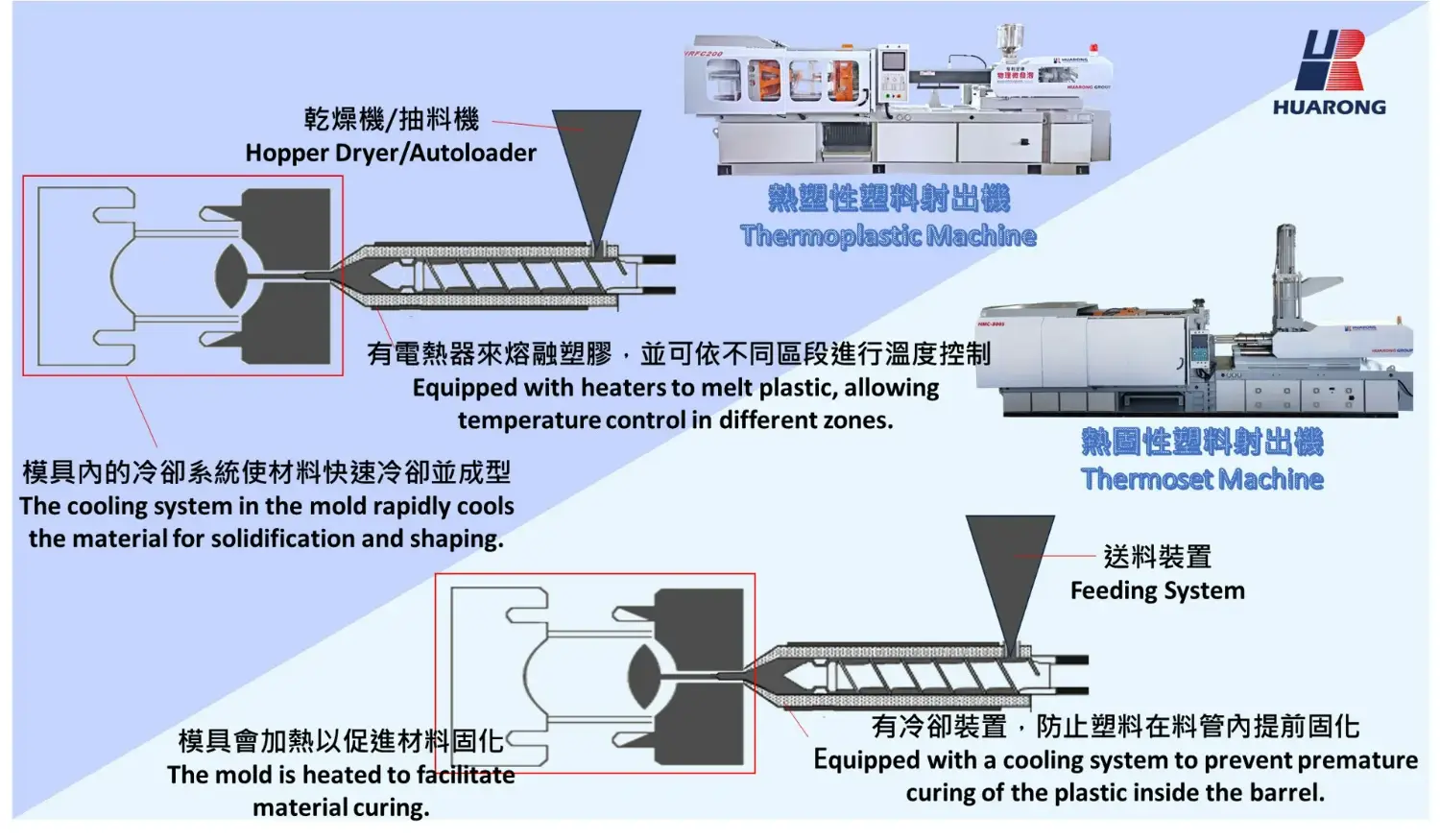

To better understand the thermoset injection molding process, it's helpful to compare it with thermoplastic injection molding:

| Feature | Thermoset Injection Molding | Thermoplastic Injection Molding |

|---|---|---|

| Material Behavior | Cures permanently, cannot be re-melted | It can be melted and reshaped |

| Heat Resistance | High, does not soften with heat | Lower, can melt under heat |

| Chemical Resistance | High, withstands harsh chemicals | Moderate, may degrade over time |

| Production Process | Longer curing time required | Faster cycle times |

| Recyclability | Not recyclable | Can be recycled and reused |

Further reading: Thermoplastic Injection Molding Explained: How It Works & Why It’s Essential

- Automotive Components

- Brake Pads: Withstand high friction and extreme temperatures.

- Ignition Parts: Provide electrical insulation and mechanical strength in demanding engine environments.

- Electrical & Electronics

- Switches: Ensures long-term durability and safety in high-voltage applications.

- Circuit Breakers: Provides insulation and protection against electrical surges.

- Medical Devices

- Surgical Tools: Handles and components must withstand repeated sterilization and high mechanical stress.

- Dental Applications: Used for dental prosthetics, molds, and equipment due to their strength and biocompatibility.

- Aerospace Components

- High-Temperature Resistant Parts: Used in aircraft engines, insulation panels, and protective covers where extreme conditions are encountered.

- Industrial Equipment

- Pump Housings: Resistant to harsh chemicals and high pressures, ensuring longevity in industrial fluid handling.

- Insulators: These are used in electrical and mechanical systems to prevent heat and electrical conductivity issues.

To select the right thermoset injection molding machine, focus on:

- A thermoset-compatible screw/barrel system

- Proper clamping force & mold heating

- Precision temperature & injection control

- Reliable venting, mold design, & automation

Successful case: Boosting Efficiency: NEOLITE ZKW's Success with Huarong's Injection Molding Machine

Thermoset injection molding is preferred for high-performance, heat-resistant, and durable components. Due to its strength, insulation properties, and cost efficiency, it is widely used in the automotive, electrical, medical, and aerospace industries.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

Previous news : Thermoset Injection Molding: Process, Benefits & Applications

Next news: Beyond Injection Molding! Analyzing Successful Transformation Through Turn-Key Automation Solutions