Success Stories: How Elevate South African Manufacturer's Manufacturing Capabilities with Two-platen

2024-04-09 16:35:19

In today's competitive manufacturing landscape, staying ahead requires embracing cutting-edge technologies. In Krugersdorp, one of our South African customer's recent acquisition of five state-of-the-art two-platen injection machines has transformed our production capabilities and propelled us to the forefront of the industry.

Founded in 2017, this South African manufacturer has quickly emerged as a key player in the automotive plastic injection molding business. Specializing in comprehensive services that encompass production, mold design, mold making, assembly, painting, packaging, and delivery, the company has established itself as a premier supplier of aftermarket automotive components. They play an integral role in the supply chain for various OEMs, contributing significantly to the automotive industry's growth.

With a robust infrastructure featuring over 300 injection molds and 16 cutting-edge plastic injection molding machines, the manufacturer has the capacity to produce a diverse range of injection-molded components, including automotive bumpers, grilles, and various other plastic car parts.

The partnership between Huarong and the South African manufacturer represents more than just a technological advancement; it signifies a strategic step toward expanding manufacturing capabilities. As the South African customer continues to innovate in the automotive plastic injection molding, the integration of Huarong's state-of-the-art machinery promises to drive them to greater success, reinforcing their dedication to excellence in this dynamic industry landscape.

The decision to invest in two-platen injection molding machines has proven to be a game-changer. Not only has Huarong enhanced their machine manufacturing capabilities, but they have also solidified their reputation as a reliable and innovative partner in the injection molding industry. As Huarong continues to grow and optimize their injection molding machines, the partnership with two-platen machines is expected to drive continued success.

Huarong recognized that the customer needed more than just machines; they required a customized solution for their injection molding operation. With 300 injection molds needed to produce a wide variety of products, the customer required a system that could efficiently manufacture these high-quality products in large quantities.

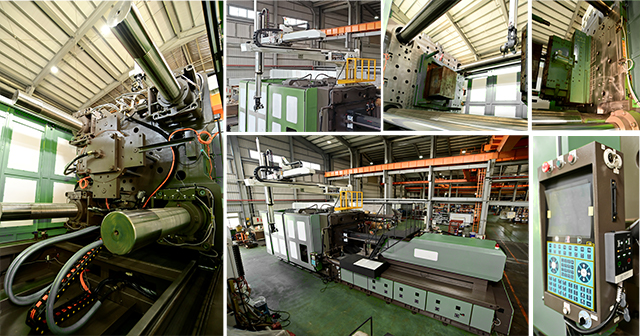

Huarong’s pioneering solution involved the installation of five state-of-the-art two-platen injection machines equipped with robotic arms, conveyors, and quick mold change (QMC) technology for automation. The robotic arms and conveyors streamline operations, automating the production process to achieve higher levels of efficiency and product consistency. The QMC technology minimizes downtime and allows for quick mold changes, maximizing productivity.

The advanced technology of the two-platen machines has been instrumental in optimizing the customer's production capacity and efficiency. The machines' ability to handle large molds and complex parts with precision has enabled the manufacturer to expand their product range and cater to a broader customer base, driving growth and success.

Key features of these machines include:

- Longer Mold Opening Stroke

- Smaller Footprint than Toggle Machines

- 20%-30% Higher Flexibility in Mold Sizes and Configurations for a Wider Range of Large Part Injection Molding

Further reading: 2 Platen Injection Molding Machine vs 3 Platen

Innovation in Large Part Molding: Huarong's Two-Platen Machine Design

Huarong's two-platen machines feature innovative design elements such as the Suspended Tie-bar Bearing Module, which supports the tie-bar, reducing energy loss due to friction and improving its natural sagging. The Patented Inner Supporting Sliding Module and the Patented Moving Platen Positioning Device allow for precise positioning and quick assembly of sliding components. These features ensure high precision and reliability during the production cycle.

The Optional Patented Tie-bar Disassembly Function addresses the inconvenience of installing and removing molds in factories with restricted heights. The detached tie-bar, located on the machine's operation side, makes it easier for operators to work.

Related product: Two Platen Machine – NRH Series

Upon machine delivery, Huarong's engineers travel to the customer’s site to oversee the installation process, ensuring the machines are set up correctly to produce various products, including car storage box accessories, SUBWAY lunch boxes, car interior pedals, and car fenders, all with an automated system for efficient operation.

As the South African manufacturer continues to innovate and grow, the partnership with Huarong's two-platen injection machines remains at the core of their success. With these cutting-edge machines, Huarong continues to elevate the standards of plastic injection molding, reinforcing their position as a leading manufacturer in the industry. For any further questions or machine needs, Huarong remains a reliable injection molding machine manufacturer, ready to assist in driving the future of manufacturing.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : Large Part Injection Molding|Plastic Machine Experts

Next news : Smart & Sustainable Manufacturing: Two-Platen Injection Molding for Global Markets