Sustainable Injection Molding Manufacturing: Two-Platen Injection Machine for Global Markets

2024-04-16 13:13:26

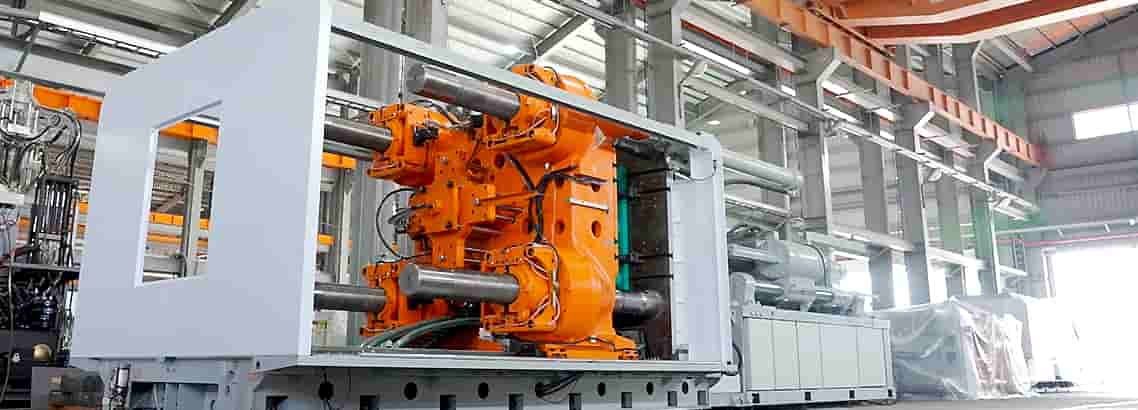

In today’s rapidly evolving industrial landscape, smart and sustainable injection molding manufacturing is not merely a trend but a necessity. Combining innovative technologies and environmentally conscious practices, it is revolutionizing the plastic industry. At Huarong, with decades of expertise in injection molding, we prioritize smart and sustainable principles in designing cutting-edge solutions, exemplified by our two-platen injection molding machine. This article delves into the significance of smart and sustainable manufacturing and how our two-platen machines support these principles.

Elements of Smart Manufacturing

Smart manufacturing leverages digital technologies to optimize efficiency and precision in the injection molding process. Key elements include:

- IoT Integration: Real-time data from IoT-enabled devices provides insights into injection molding machines performance, energy usage, and production metrics, enabling immediate corrective actions.

- Real-Time Monitoring and Control: Advanced analytics, paired with sensor-driven monitoring systems, ensure seamless production with enhanced quality control.

- Robotics: Automated robotic systems perform complex tasks such as part removal, assembly, and inspection, reducing manual errors and improving overall production speed.

Elements of Sustainable Manufacturing

Sustainable manufacturing emphasizes reducing environmental impacts while enhancing resource efficiency. Essential elements include:

- Efficient Resource Utilization: By optimizing the use of raw materials, energy, and water, manufacturers can minimize waste and environmental footprint.

- Waste Reduction: Implementing recycling programs and adopting energy-efficient processes significantly cut production and post-consumer waste.

- Minimized Environmental Impact: Reducing greenhouse gas emissions and limiting air and water pollution contribute to a greener planet.

The importance of smart and sustainable injection molding lies in addressing critical environmental, societal, and economic challenges.

- Environmental Responsibility: Climate change and resource scarcity demand sustainable solutions to reduce pollution, emissions, and waste.

- Cost Efficiency: Smart technologies optimize processes, reduce energy consumption, and lower operational costs, enhancing profitability.

- Improved Forecasting: Advanced analytics enable manufacturers to match production precisely to demand, avoiding overproduction and inventory surplus.

- Worker and Community Safety: Modern practices enhance safety standards for workers and nearby communities.

Benefits of Smart and Sustainable Manufacturing

- Reduces energy and resource consumption.

- Improves product quality through precise manufacturing.

- Aligns with global sustainability goals, boosting brand reputation.

Huarong’s two platen injection molding machines embody the principles of smart and sustainable manufacturing, addressing the needs of modern factories. Their advanced design promotes efficiency, precision, and environmental responsibility, making them an ideal solution for manufacturers worldwide.

Related product: Two--Platen Injection Machine – NRH Series

Smart Manufacturing and Automation

Huarong integrates smart factory management systems and cutting-edge automation technologies into its two-platen machines:

- Robotic Arms: Enhance production speed, precision, and consistency while reducing human intervention.

- Data-Driven Systems: Our HFM System enables real-time monitoring, predictive maintenance, and optimization of production processes.

Related product: Smart Factory Management – HFM System

Related product: Injection Molding Robot - Manipulator Arm

Green and Sustainable Development

Huarong’s commitment to sustainability is evident in the innovative features of our two-platen machines:

- Servo Motor System: With over 70% energy efficiency, it delivers rapid response times (40ms) and exceptional repeatability (0.2%).

- Direct Drive Material Storage Motor:

- Energy Saving: Enhances material storage efficiency by 26% compared to standard systems.

- Improved Production Cycles: Enables simultaneous storage and mold operations, reducing cycle times.

- Extended Equipment Lifespan: Minimizes mechanical wear with axial storage motion.

- Microcellular Foam Injection Molding Technology: Reduces the weight of products, enabling manufacturers to use less plastic material while maintaining structural integrity, contributing to material cost savings and sustainability.

Related technology: Power Unit > Servo System

Related technology: Injection Unit > Energy-Efficient Direct Drive Material Storage Motor

Related technology: Injection Unit > Microcellular Foam Injection Molding Technology

Global Plastic Injection Market Trends

The global plastic injection molding market is on a growth trajectory, expected to reach USD 266.1 billion by 2030, with a CAGR of 4.8% from 2021. This growth is driven by increasing demand across industries like automotive, packaging, and medical. Huarong's two-platen machines are ideal for this market, being more compact than traditional three-platen injection machines (toggle injection machine) for medium and large part injection molding, and has a longer and more flexible mold opening stroke, allowing it to produce more wide range of products.

The global plastic injection molding market is projected to reach USD 266.1 billion by 2030, driven by demand in sectors such as automotive, packaging, and medical. Huarong’s two-platen machines are ideally suited for these industries:

- Compact Design: Requires less floor space compared to traditional three-platen machines.

- Flexible Mold Opening Stroke: Facilitates production of diverse product ranges, from medium to large parts.

Further reading: 2 Platen Injection Molding Machine vs 3 Platen

Smart and sustainable manufacturing is not just the future of the plastic injection molding industry—it is the present. By investing in advanced technologies, manufacturers can achieve improved efficiency, reduced waste, and significant contributions to a cleaner planet.

At Huarong, we remain committed to driving innovation and sustainability in the industry by:

- Developing advanced injection molding machine technologies that improve efficiency and precision.

- Offering smart factory solutions to optimize operations and minimize waste.

- Partnering with customers to implement sustainable manufacturing practices.

By aligning our efforts with global sustainability goals, we ensure that our customers are equipped for the challenges and opportunities of the future. For more details about our solutions in sustainable injection molding, visit Huarong.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777 #521

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : Success Stories: How Elevate South African Manufacturer's Manufacturing Capabilities with Two-platen

Next news : CHINAPLAS 2024 | Huarong Exhibition Complete Guide