Innovations at ChinaPlas: A Recap of Huarong's Injection Molding Solutions

2024-05-03 09:07:31

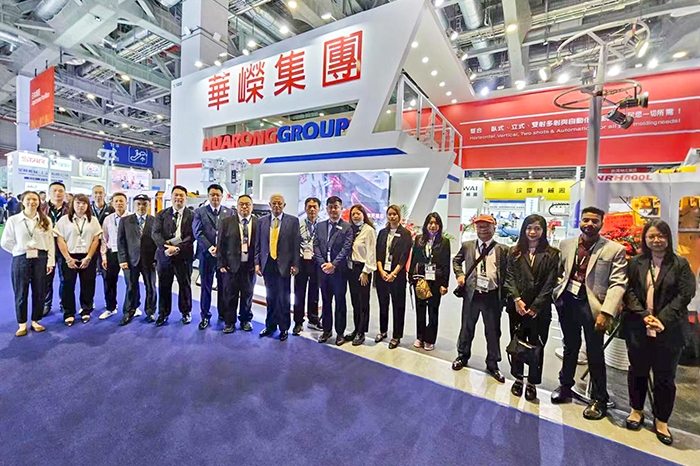

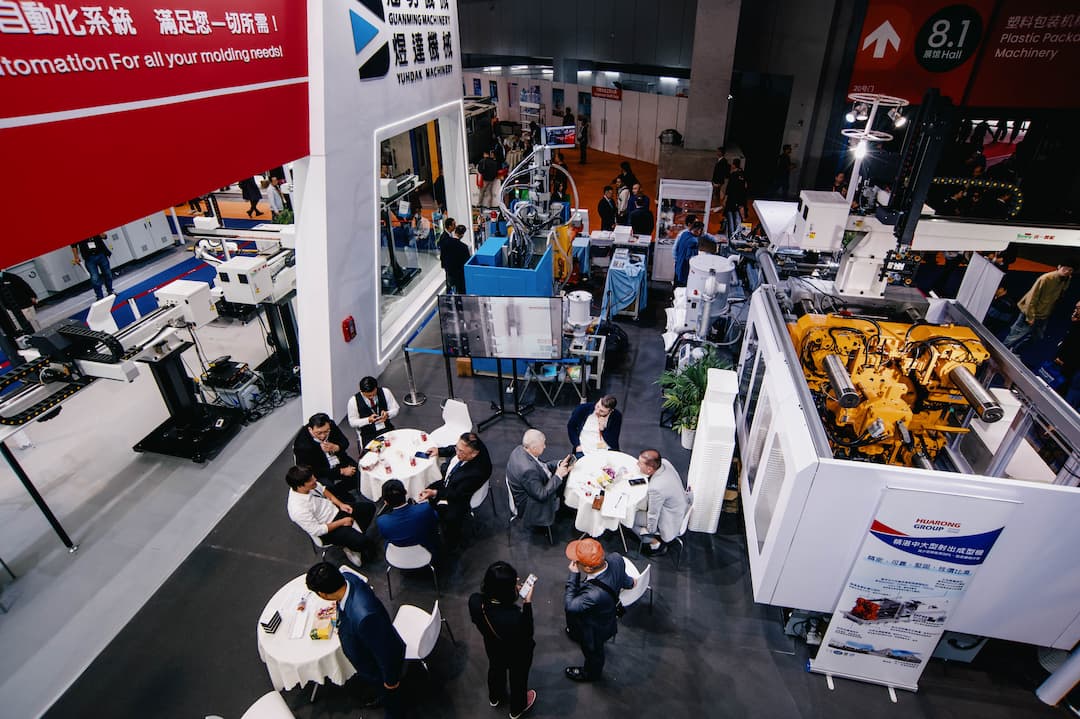

Every year, the ChinaPlas exhibition serves as a platform for industry leaders to showcase their latest innovations and advancements in plastics and rubber technology. Recently, it concluded at the National Exhibition and Convention Center in Shanghai, heralding a triumphant showcase of cutting-edge injection molding and manufacturing solutions by Huarong Group.

Huarong's presence at ChinaPlas was marked by a stunning display of cutting-edge injection molding machines, vertical injection molding machines, and solutions. The booth attracted a large number of visitors, including industry professionals and potential customers. As the core spirit of "Industrial alliances create value for customers ", Huarong's focus at the event was on highlighting our commitment to innovation and technological advancement in the field of injection molding to help customers reduce costs, enhance efficiency, and embrace transformative upgrades.

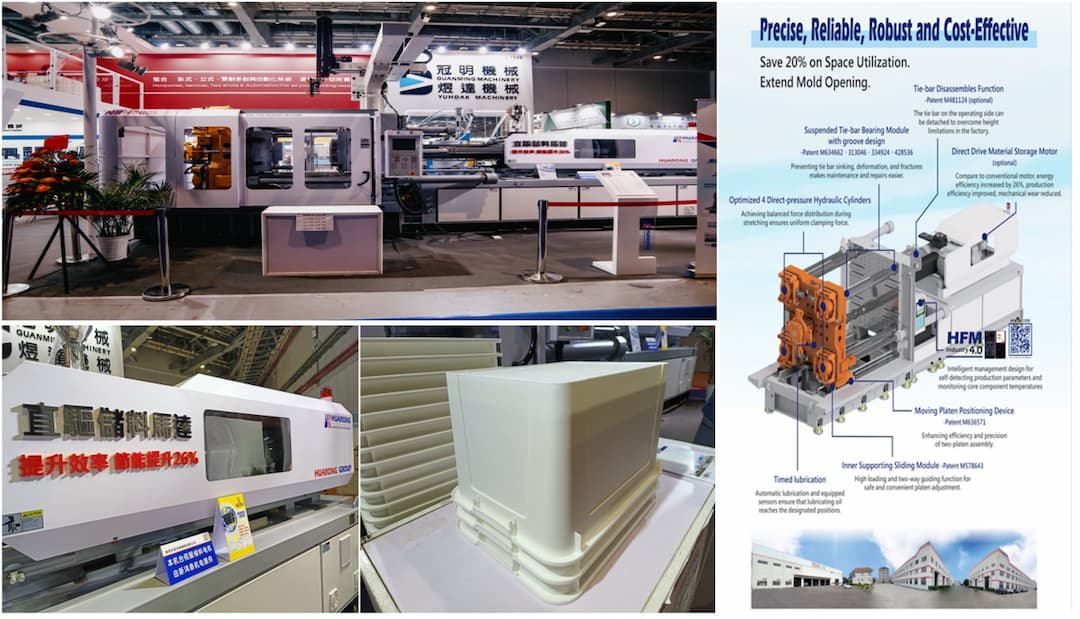

Huarong's expertise in injection molding is not just well-established, but also trusted by a wide range of industries. Our machines are known for their precision, reliability, and efficiency, making them the go-to choice for many manufacturers around the world. One of the key highlights of Huarong's showcase at ChinaPlas was the unveiling of the latest Two-Plate Injection Molding Machine, a testament to our commitment to delivering high-quality, reliable products that revolutionize large part molding with its innovative design features.

- The Suspended Tie-bar Bearing Module supports the tie-bar, reduces energy loss due to friction, and effectively improves its natural sagging, ensuring smooth and precise operation.

- Patented Inner Supporting Sliding Module and the Patented Moving Platen Positioning Device. These components allow sliding elements to be quickly assembled for precise positioning, enhancing the machine's overall accuracy and efficiency.

- To ensure optimal performance, customers are regularly alerted during the production cycle to use an inspection jig and gauge to check the height of the moving platen center. This helps prevent abnormal coaxiality of the two platens, ensuring consistent and high-quality molding results.

- The Optional Patented Tie-bar Disassembles Function addresses the challenge of installing and removing molds in factories with restricted heights. The function allows for the tie-bar to be detached and located on the machine's operation side, making it easier for operators to work and increasing overall operational efficiency.

Related product: Two--Platen Injection Machine – NRH Series

In addition to technological advancements, in response to industry trends favoring sustainable and smart solutions, Huarong also emphasized the commitment to sustainability in manufacturing that incorporates the Servo Motor System and Direct Drive Material Storage Motor into a two-platen injection machine.

- Servo Motor System: This offers exceptional energy efficiency, with over 70% efficiency, a rapid response time of 40ms, and outstanding repeatability of 0.2%.

- Direct-drive material Storage Motor: This motor enhances energy storage efficiency by 26% compared to standard methods. It improves production efficiency by eliminating the need for additional hydraulic circuit control. The motor's shut-off nozzle or mold valve gate function allows for simultaneous opening and storage, reducing the molding cycle and improving overall production efficiency.

For smart manufacturing integration, Huarong is at the forefront of integrating smart manufacturing practices into its injection molding machines, including HFM systems, transforming them into smart machinery capable of controlling production conditions and self-inspection in real-time. Besides, Huarong has introduced servo motor 3-axis to 6-axis manipulators for fully automated production in smart factories.

- Manager x HFM systems:

- Enables a comprehensive view of the entire plant's status.

- Assists in quick and accurate decision-making.

- Manages platform authority.

- Production Management Department x HFM systems:

- Provides quick and accurate monitoring of production progress.

- Facilitates autonomous data collection.

- Improves production efficiency.

- Exported data can be integrated with customer management systems.

- Operator x HFM systems:

- Receives instant alert notifications.

- Enables proactive maintenance through intelligent inspection.

Related product: Smart Factory Management – HFM System

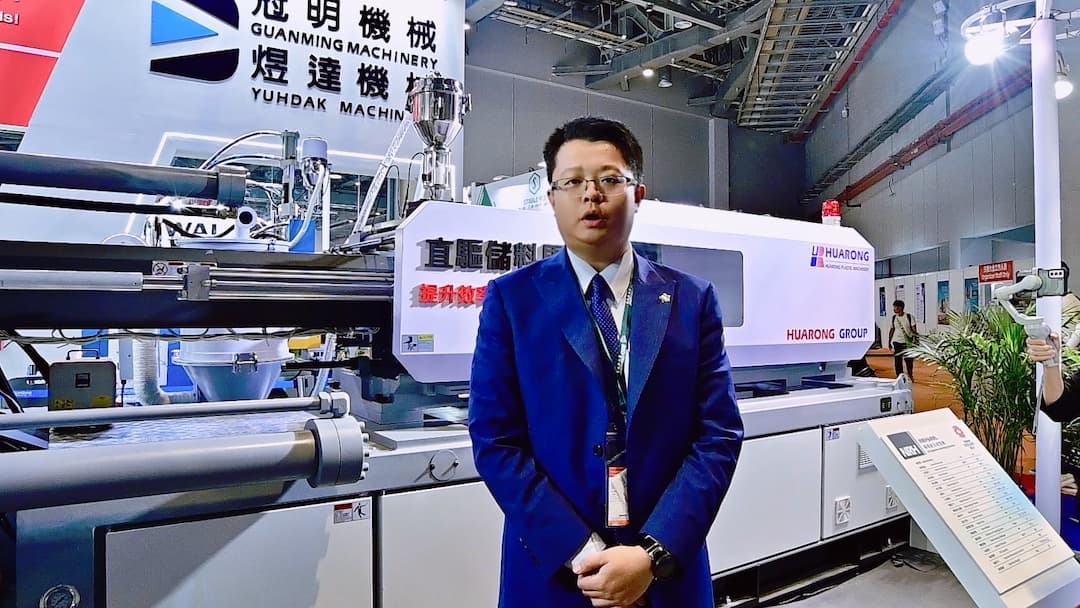

In an exclusive interview, Mr. Ryan Hsiao, Senior Manager of Huarong Group, highlighted the company's strategic priorities and innovative drive. He emphasized the importance of quality products and advanced technology, underlining Huarong's commitment to being the customers' molding partner that meets all injection molding needs.

As the demand for injection molding continues to grow, Huarong is poised to lead the way with its innovative solutions and customer-centric approach. Its focus is on enhancing machine performance, improving sustainability, and advancing smart manufacturing practices. The company remains committed to pushing the boundaries of injection molding technology, ensuring that it stays at the forefront of the industry for years to come.

Further reading: Smart & Sustainable Manufacturing: Two-Platen Injection Molding for Global Markets

The fourth-day Chinaplas has ended successfully. Thanks to the support of all the partners and customers who visit us. We cherish all the moments of being with you. During the Chinaplas, there is not only exhibiting the machines but also cutting-edge injection molding and manufacturing solutions. Let us review the wonderful moments through the video.

What sets Huarong's injection molding solutions apart from competitors?

Huarong's injection molding solutions are known for their advanced features, superior performance, and commitment to sustainability, setting them apart from competitors in the industry.

How does Huarong incorporate sustainability into its products?

Huarong incorporates sustainability into its products by using eco-friendly materials, optimizing production processes to reduce waste, and integrating energy-efficient technologies into its machines.

Can Huarong's injection molding machines be customized for specific manufacturing needs?

Yes, Huarong offers customization options for its injection molding machines to meet the specific requirements of manufacturers, ensuring optimal performance and efficiency.

What can we expect from Huarong in terms of future innovations in injection molding technology?

Huarong is committed to pushing the boundaries of injection molding technology, with a focus on enhancing performance, sustainability, and smart manufacturing integration. Expect to see more groundbreaking innovations from Huarong in the future.

Huarong's participation at ChinaPlas was a resounding success. We showcased the latest innovations in injection molding technology, from new machines with advanced features to sustainable practices and smart manufacturing integration. Huarong's unwavering commitment to excellence, innovation, and customer satisfaction. If you are interested in an injection molding machine, please contact Huarong.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : CHINAPLAS 2024 | Huarong Exhibition Complete Guide

Next news : What Is Overmolding? Process, Advantages, and Applications