Injection Molding Machine Manual at Huarong Machine

2024-08-08 13:47:14

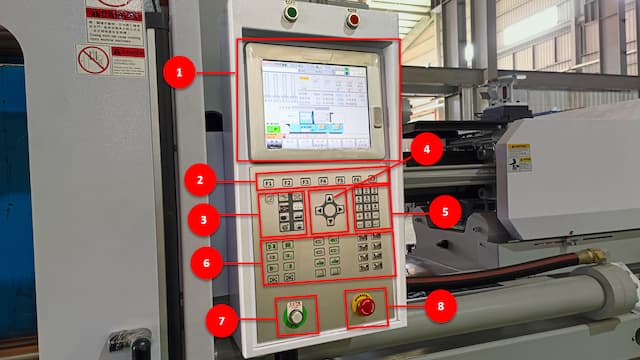

Many new operators of Huarong machines struggle with unfamiliar controllers. This comprehensive guide covers button functions and is designed for your ease and comfort.

The injection molding machine plc controllers are designed for user efficiency. They are segmented into eight distinct parts, each with specialized functions. Familiarizing yourself with these features is the first step toward efficient injection molding machine operation.

Instruction Manual

- LCD and Touch Screen: Centralized display for monitoring machine operations.

- F1 ~ F7 Buttons: These buttons allow you to change the screen page and convert it to the selected function screen.

- Mode Selection, Pump, and Heater Buttons: These are control buttons for switching operational modes and managing pump and heater functions.

- Cursor Movement Buttons: Navigate through different settings with these directional keys.

- Number Buttons: Input precise numerical values for various parameters or enter English.

- Action Buttons: Use these buttons to execute specific tasks, such as opening and closing molds, moving injection units, and more.

- Power Up Button: Initialize the machine's power for operation.

- Emergency Button: Instantly halt operations in an emergency, ensuring safety.

The following section will detail the above mode selection, pump, heater, and action buttons and introduce how to use each function while manually operating the injection machine.

Mode Selection, Pump, and Heater Button Operations

These buttons are crucial for setting the machine’s operational mode and controlling essential functions like the pump and heater. Here’s a detailed breakdown of their functionalities:

Action Button Functions and Procedures

The Action buttons give you direct control over various machine functions, making them critical for manual operation.

The injection molding controller is a critical component that ensures the precise operation of your injection molding machine. However, like any sophisticated technology, controllers can occasionally encounter issues that disrupt production. Here are some common problems associated with injection molding controllers and their solutions:

Controller Screen Freezes or Becomes Unresponsive

Issue: The controller screen becomes unresponsive or freezes, preventing operators from adjusting or monitoring the machine’s status.

Solution: First, check for any visible signs of damage or loose connections in the control panel. Restart the controller by powering it off and on again. If the issue persists, perform a factory reset according to the machine’s manual. Ensure that the controller software is up-to-date, and consider reinstalling or upgrading the software if necessary. If the problem continues, contact technical support for further assistance.

Incorrect Parameter Settings

Issue: The machine does not perform as expected due to incorrect parameter settings, leading to defects in molded parts or inconsistent production.

Solution: Review the controller’s parameter settings to ensure they align with the specifications for the current molding job. Verify that temperature, pressure, speed, and cycle time settings are correct. If unsure about the correct settings, consult the machine’s operation manual or contact technical support for guidance.

Error Codes Displayed on Controller

Issue: The controller displays error codes or alarms that interrupt machine operation.

Solution: Refer to the machine’s manual or controller documentation to understand the meaning of the error codes. Many controllers have a built-in diagnostic tool that provides detailed information about the issue. Address the underlying cause of the error, whether it’s a mechanical fault, electrical issue, or sensor malfunction. Clear the error codes after resolving the problem and perform a test run to ensure regular operation.

Inaccurate Temperature Readings

Issue: The controller shows incorrect temperature readings, affecting material viscosity and product quality.

Solution: Inspect the thermocouples and temperature sensors for any signs of damage or misalignment. Replace faulty sensors or recalibrate them as necessary. Ensure that the temperature settings on the controller match the requirements for the material being used. It’s also essential to check for software bugs or glitches that might cause incorrect readings and update the controller firmware if needed.

Communication Errors Between Controller and Machine Components

Issue: The controller fails to communicate appropriately with other machine components, such as the hydraulic system or injection unit, leading to operational delays or failures.

Solution: Check all cables and connectors between the controller and machine components for wear, damage, or disconnection signs. Tighten any loose connections and replace damaged cables. Verify that all communication settings in the controller are configured correctly. If the issue remains unresolved, reset the controller’s communication settings and perform a full system reboot.

Controller Overheating

Issue: The controller becomes excessively hot during operation, potentially leading to component failure or reduced performance.

Solution: Ensure the controller is installed in a well-ventilated area with adequate cooling. Clean any dust or debris from the controller’s vents and cooling fans. Check the ambient temperature of the machine environment to ensure it’s within the recommended operating range. If overheating persists, consider installing additional cooling systems or upgrading the controller’s internal cooling components.

Understanding the manual operation of Huarong machines to maximize their performance and ensure operational safety. Following this detailed guide, operators can gain precise control over their machines, leading to efficient and optimized production processes.

If you need further assistance or have any questions, please contact Huarong. We are an experienced injection molding machine manufacturer dedicated to providing expert guidance and support to help you achieve your injection molding needs.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news: How Our Vertical Injection Machines Produce High-Quality Tubes for CPAP | Success Story

Next news: Celebrating Innovation and Excellence: Huarong at TaipeiPlas 2024