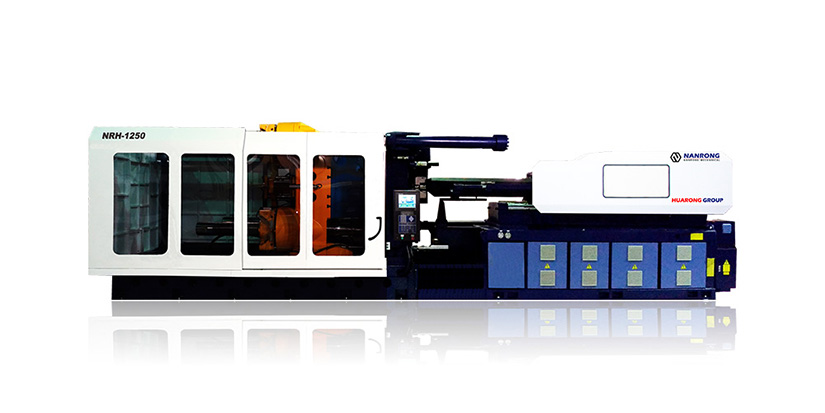

Two platen injection molding machine – NRH series

ー Preferred Choice for Medium and Large Size Injection Machine

The NRH series comprises two-platen structures engineered for superior performance in molding complex, large-sized plastic parts. With clamping forces ranging from 500 to 5000 tons, these machines are ideal for large-part injection molding that reduces machine length by up to 30% and extends mold opening strokes.

Key Features of NRH Series Two-Platen Injection Molding Machine

Our two-platen injection machines are designed with innovative patented technologies that enhance precision and robustness. Key features include the patented moving platen positioning device (Patent M636571) and the suspended tie-bar bearing module (Patent M634662), both of which ensure optimal machine performance and longevity."

Patented Moving Platen Positioning Device (Patent M636571)

- Equipped with jig and gauge positioning modules for quick coaxiality determination.

- Enhances assembly precision and speed.

- Ensures accurate alignment of the two platens.

Optimized Hydraulic System for Uniform Clamping Force

- Designed with four sets of double half nuts and synchronized hydraulic design.

- Ensures balanced force distribution, minimizing wear and maximizing the machine's lifespan.

Advanced Temperature Monitoring for Component Protection

- Real-time monitoring of core component temperatures.

- Instant notifications for abnormal temperature increases.

- Ensures effective lubrication to prevent component damage.

Efficient Lubrication with Timed Sequential Valves

- Uses a distribution valve system for precise lubrication.

- Sensor integration ensures oil reaches all lubrication points.

- Reduces wear and extends machine lifespan.

Patented Suspended Tie-Bar Bearing Module (Patent M634662)

- Adjustment structures are externally accessible for easy maintenance.

- High loading and two-way guiding functions enhance performance.

- Ensures precise assembly without manual adjustments, improving efficiency.

Patented Inner Supporting Sliding Module (Patent M578643)

- Adjustment structures are externally accessible for easy maintenance.

- High loading and two-way guiding functions enhance performance.

- Ensures precise assembly without manual adjustments, improving efficiency.

Patented Outward-Opening Safety Door (Patent M257955)

- Two-stage design for easy and quick access.

- Spacious opening facilitates mechanical maintenance.

- Enhances safety and reduces maintenance time.

Patented Groove Design with Tie-bars (Patent 313046, 334924, and 428536)

- Necked-down tie-bar design in the platen section.

- Eliminates shear forces to prevent tie-bar fractures.

- Increases machine durability and reliability.

Autonomous Detection Functionality

- Provides regular alerts for platen center height inspection.

- Optional monitoring of 13 production parameters for stability.

- Early notification of anomalies to reduce defects and damage.

Patented Tie-bar Disassembles Function (Patent M481124)

- Detachable upper tie-bar for easier mold entry.

- Overcomes vertical space constraints in workshops.

- Enhances flexibility in limited space environments.

Advantages of Two-Platen Injection Molding Machine

1. Space-Saving Design with Reduced Machine Length

The two-plate machine design significantly reduces machine length by embedding the mold clamping cylinders. This space-efficient design shortens dimensions by 20% to 30% compared to toggle-type machines, improving workshop utilization.

- Embedded mold clamping cylinders reduce machine length.

- Saves 20% to 30% space compared to toggle-type machines.

- Enhances workshop space utilization.

2. Extended Mold Opening Stroke for Versatile Applications

Designed for flexibility, the two-platen machines feature rapid, fully automatic mold adjustment functions and an extended mold opening stroke. This versatility ensures the machinery can adapt to various production needs with ease.

- Rapid and automatic mold adjustment for convenience.

- Extended mold opening stroke for versatile applications.

- Enhances operational flexibility to meet production requirements.

Machine Applications

ー Utilized across diverse industries, such as automotive, household appliances, electronics, and other medium- to large-sized plastic products.

- Automotive Parts: Bumpers, dashboards, interior components.

- Public Facilities: Outdoor garbage bins, road signs, traffic cones.

- Logistics Industry: Pallets, plastic crates, transport boxes.

- Household Appliances: Televisions, refrigerators, screens, blenders.

Why Choose Huarong for Your Injection Molding Needs?

1. Industry-Leading Expertise and Innovation

With over 40 years of experience, Huarong is a leader in injection molding technology. Our two-platen machines are backed by numerous patents, ensuring top-tier performance and reliability. We are committed to delivering innovative solutions that enhance production efficiency and product quality.

2. Comprehensive Support and Customization

We offer comprehensive support and customization options to meet your specific injection molding needs. Our team of experts is dedicated to providing high-quality machines and services, helping you achieve optimal production outcomes.

Success Stories with Two-Platen Machines

Story 1: Plastic Pallet Production

Pallets are essential tools in logistics and warehouse management, facilitating the stacking of goods, saving storage space, and enabling convenient, safe transportation and storage. So why choose the injection molding process for plastic pallets?