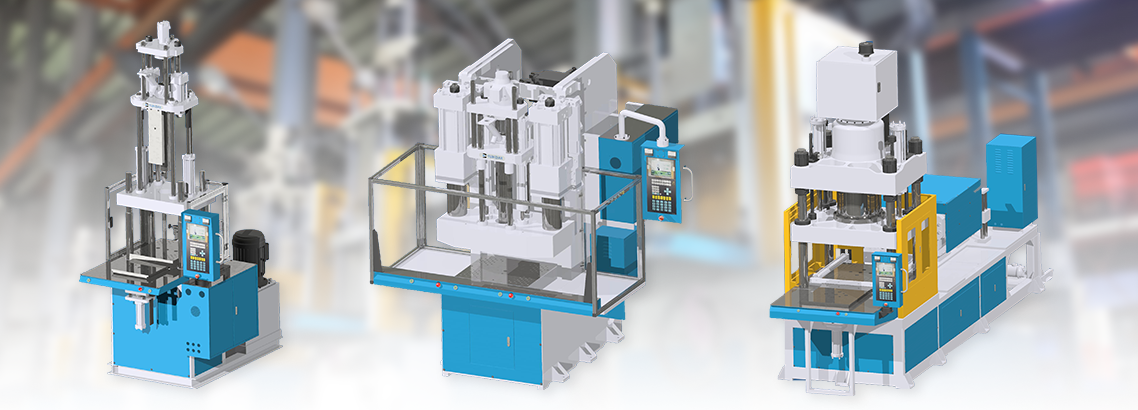

Vertical Injection Molding Machine

At HUARONG GROUP, we specialize in manufacturing advanced vertical injection molding machines designed to meet the diverse needs of modern industries. These machines offer a unique combination of precision, efficiency, and versatility, making them an ideal choice for various applications ranging from automotive to consumer goods, electronics, and medical devices. Our commitment to innovation and quality ensures that each machine we produce is engineered to deliver exceptional performance, providing our customers with reliable and high-quality solutions that enhance their production capabilities.

Overview of Vertical Injection Molding Machines

Vertical injection molding machines differ from their horizontal counterparts in that they have a vertical clamping and injection unit, making them ideal for precise insert molding applications. Our vertical injection molding machines offer various models with different clamping forces, injection units, and customization options to fit your production needs.

- Injection Units: Available in horizontal or vertical configurations to suit various production requirements.

- Clamping Units: Options for sliding or rotary tables and tie-bar or tie-bar-less designs.

- Precision Control: Advanced servo motor technology ensures precise and consistent molding.

- Energy Efficiency: Optimized for lower energy consumption without compromising performance.

- Versatility:Suitable for various applications, including insert molding, overmolding, and more.

Key Features

Superior Injection Control and Precision

Our vertical injection molding machines are designed for seamless integration, providing precise and effortless placement of parts into the mold. The advanced control systems ensure meticulous regulation of injection speed, pressure, and temperature for high-quality, efficient production.

Enhanced Space Utilization

Our vertical injection molding machines save floor space by efficiently utilizing vertical space, thereby increasing machine density and expanding production capacity without requiring additional square footage.

Versatility in Molding Applications

Our vertical injection molding machines are ideal for producing complex parts in various industries. The vertical clamping and injection units are well-suited for multi-component molding processes, accommodating diverse products with varying material properties. Whether working with plastic, rubber, or other materials, our machines offer the flexibility to meet specific application requirements, making them suitable for various industries.

High Precision and Compact Design

These machines are ideal for injection molding of medium and small products with inclusions and inserts. The dual-cylinder injection system provides high pressure for rapid operation, making it perfect for thin-walled items. The direct-pressure mold clamp ensures even force distribution, maximizing precision and operational smoothness.

Optimized for Efficient Manufacturing

Our vertical injection molding machines have a compact design and a direct-pressure mold closing mechanism, ensuring consistent stress distribution and robust stability. Optional features such as a sliding table or rotary table can be added to significantly enhance production efficiency. These machines are space-saving and are ideal for factories with limited space, offering a practical solution that does not compromise on performance or quality.

Vertical Injection Vertical Clamping

- This machine can be equipped with sliding or rotary tables, with options for tie-bar or tie-bar-less designs. This lets operators pick up or place inserted parts on the mold simultaneously, enhancing work efficiency and automation capabilities.

Machine models

Horizontal Injection Vertical Clamping

- Suitable for various insert molding and overmolding tasks, this machine offers tie-bar or tie-bar-less configurations. Including sliding or rotary tables improves operational efficiency by enabling concurrent part handling and mold operations.

Machine models

Special Injection Vertical Clamping

- HUARONG’s special vertical machines are custom-developed to meet unique production requirements.

Machine models

Sucessful Case Study

Producing a dental floser of the highest quality requires extra care and precision. Here’s how to use advanced production techniques, tools and materials for the perfect outcome.

FAQ

Further reading: Vertical Injection Molding vs Horizontal Injection Molding for Plastic Components

Further reading: Comprehensive Guide to Vertical Injection Molding Machines

Injection Machine Inquiry

Would you be interested in learning more about our vertical injection molding machines?

Please reach out to us today to discuss your production needs or request a quote.